Haskell Ag Lab Case Study

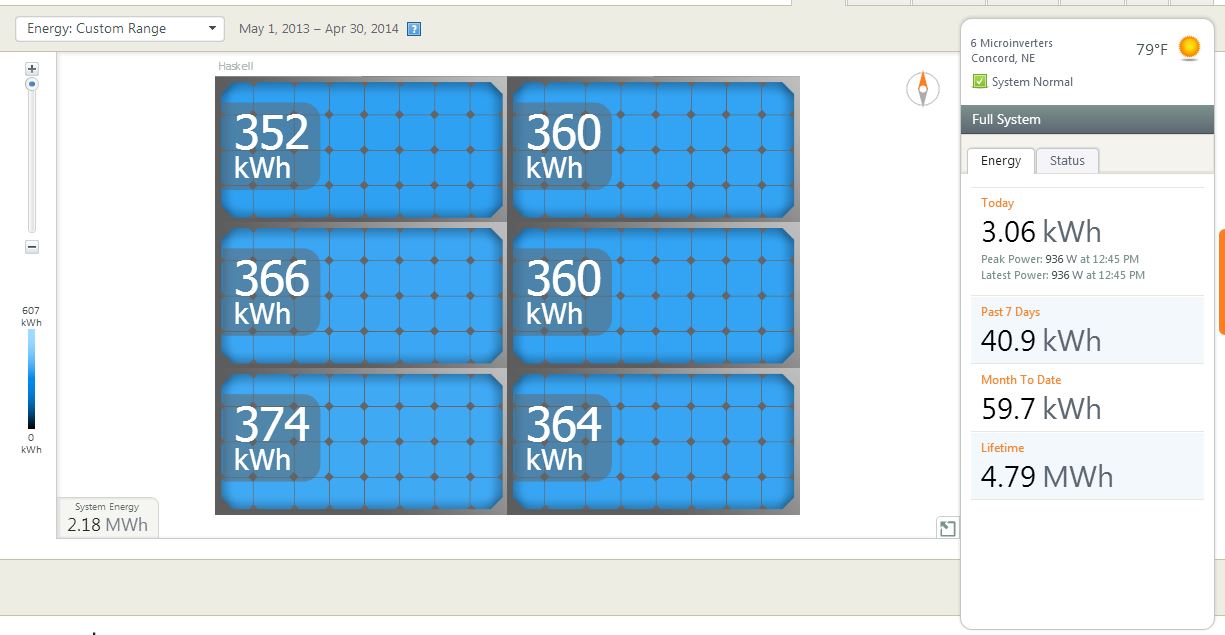

Six solar panels consisting of panels from 4 different manufacturers make up the solar array at the Haskell ag lab in Northeast Nebraska

Total Cost

1.39 kilowatt solar array

$3.25 per Watt installed

(larger = lower cost per Watt)

Total cost $4,517

Estimated Production

- 1.39 kW x 5 hour per day x 365 days per year x 0.80 (system efficiency factor) = 2,029 kWh per year

- PV Watts (pvwatts.nrel.gov) = 2081 kWh per year

Actual Production

2,114 kWh per year June 2012 to May 2013

2,241 kWh per year June 2013 to May 2014

2,025 kWh per year June 2014 to May 2015

2,180 kWh per year June 2015 to May 2016

2141 kWh per year June 2016 to May 2017

2159 kWh per year June 2017 to May 2018

1976 kWh per year June 2018 to May 2019

1963 kWh per year June 2019 to May 2020

Simple Payback

2,140 kWh (4 year ave) x $0.10 per kWh = $214 in electricity

Payback $4,517/$192 = 21 years

REAP grant and fed tax credit Federal tax credit only

Payback = 11.4 years Payback = 14.4 years

Rate of Return = 7.2% Rate of Return = 4.7%

Net Present Value = $1,688 Net Present Value = $835

System Life Expectancy 30 Years

(Rate of Return and Net Present Value calculated at 30 years)

What we have learned (Haskell Ag Lab):

INSTALLATION:

Piece of cake but don’t forget the electrical code. Solar PV installation is relatively simple especially with microinverters, yet the balance of the system components like grounding, and wire management are important to meet all electrical code compliance. Be sure you know what is required for code compliance. This is where an experienced installer can help. We chose microinverters for the flexibility of monitoring each individual panel. Microinverters can be more expensive than one larger string inverter yet are a good choice when part of the array may be shaded or individual monitoring is desired.

SOLAR IS ROBUST:

There are plenty of brands of good panels on the market. Many modern silicon solar panels are high quality and are sold by many brands. The brands we chose came from both US and Chinese manufactures. Chinese made panels are common due to great scale up in Chinese production. Consider Chinese panels that come from reputable companies perform similarly to domestic panels. Consider the company and warranty when choosing a panel.

SOLAR IS BORING (in a good way):

A solar panels best attribute is the fact it has no moving parts. This same attribute also makes it boring. So far outside of human error our boring solar panels have functioned flawlessly for 3.5 years which we cannot say the same for our wind turbines. A tracking solar array will give more output for the same size system but will add moving parts which have a much higher likelihood of failure. Keeping it simple is the way to go. We faced our solar array south and tilted at approximately 42 degrees. We have the ability to adjust tilt based on the season and have adjusted them to a higher angle in the winter to take advantage of the lower sun angle in the winter. In order to keep it simple we did not use batteries to store the electricity. Grid tied systems don’t provide backup power but they do cost less and have less maintenance than battery backup systems.

SOLAR IS SCALABLE:

One panel or one hundred just do the math. Our experience with just six panels would translate to 10, 60 or 600 panels. Only difference being the space required for the array. Currently in 2015 solar PV systems will cost between $3 and $4 per Watt installed with the lower cost per Watt for larger systems and slightly higher cost for smaller systems. The energy production would scale almost perfectly based on the number of panels.

SHATTERED SOLAR PANELS:

In May of 2014 two of our six panels had shattered glass. The glass surface was shattered by what looks like hail stones (The Trina solar panel was rated to withstand a one inch hail stone at 50 miles per hour). Upon close examination of the data it was determined that there were no storms at the time and date of the damage and possibly a rock thrown from a shredder may have caused the damage. The broken panels still produced power yet at about half the rate of the unbroken panels. We would expect the panels would have eventually failed due to corrosion from water infiltration. We replaced the broken panels at a cost of about $200 each including shipping. We were able to reuse all other components such as microinverters etc.

CONCLUSIONS:

High quality components are available and unfortunately there are also some low quality options available. Do your homework to find good components. Solar modules, inverters and racking are available from local or regional installers. Do your homework regarding installers.

The economics of solar is somewhat more complex. Solar has declined in price in recent years and thus the payback period is considerably lower than small wind. Each individual will have to determine if the economics is right for them. The goals for each person may also differ, for example a person who values the clean energy may be happy with a longer payback than someone looking at it as an investment.