Content

Systems which use sunlight to generate electricity. Photovoltaic (PV) cells have been used since the 1950's yet it was not until the 1980's and high government subsidies helped homeowners, and businesses access the technology. More recently since 2010 cells have declined in price dramatically allowing for larger scale development of solar and more adoption of solar PV for homes, farms, and businesses. Solar installed behind the electric meter for use at a home, farm, or business is called distrubited solar.

Solar Workshop Distributed Solar for Homes Farms and Businesses

https://www.youtube.com/watch?v=i0jLsSxAGzQ&t=15s

Presented December 2022 and January 2023

Presentation PDF

Workshop Handout

Steps in the Solar PV Process for Homes, Farms or Businesses

| Steps in the process of installing a grid connected solar PV system | Who is responsible/Who Should Be Involved |

| 1. Study electric bills and electric use. Energy efficiency should always be first | System Owner |

| 2. Solar homework: Write down why you want solar. List all your goals. | System Owner |

| 3. Seek quotes from multiple installers. Talk to installers and ask lots of questions | System Owner |

| 4. Contact the Utility | Owner and Installer |

| 5. System Design | Installer with input from Owner |

| 6. Procurement of all equipment | Installer |

| 7. Permitting (building permit, engineering, etc: will depend on local regulations) | Installer |

| 8. Structure (build structure for ground mount or inspect and modify structure for roof mount) | Installer |

| 9. Solar rail or mounting installation | Installer |

| 10. Solar module (panel) installation (may include inverter installation if using microinverters) | Installer |

| 11. Electrical permit | Installer and/or electrician |

| 12. DC wiring and grounding | Installer |

| 13. Inverter installation (string inverter) | Installer |

| 14. AC wiring: Install AC shutoff as required by electric code | Installer and/or electrician |

| 15. Electric inspection | Electrical inspector contacted by installer |

| 16. Install safety labeling required under electric code | Installer |

| 17. Utility interconnection agreement | Owner, Utility, Installer guidance |

| 18. Metering equipment (Utility site inspection may happen at this time) | Utility |

| 19. Turn it on! (monitoring equipment setup) | Owner and Installer |

These steps are a general guide to the installation process this is a list of major steps in a logical order. It is important to involve the utility at an early stage to ensure there is good communication. (Federal law (Public Utility Regulatory Policy Act of 1978) requires a utility to connect renewable systems to the grid and purchase the excess generation yet installers and owners need to work with the utility to meet safety and interconnection requirements). In many locations an owner may also play the role of installer in which case it is critical the owner knows and follows all electrical and building code requirements for thier area.

Solar Photovoltaic Systems

The complete solar system is called a Solar Photovoltaic (PV) System and is also called a solar array or simply a solar system. A solar system is an array of solar panels that have been wired together to produce the correct amount of voltage. Each solar panel is made up of solar cells, and each solar cell is made from silicon. Silicon is a chemical element that acts as a semiconductor allowing sunlight to produce freely flowing electrons for electricity.

A solar panel is made up entirely of the same type of solar cells and this determines the efficiency rating of the panel. Once the panels are wired together they are considered an array.

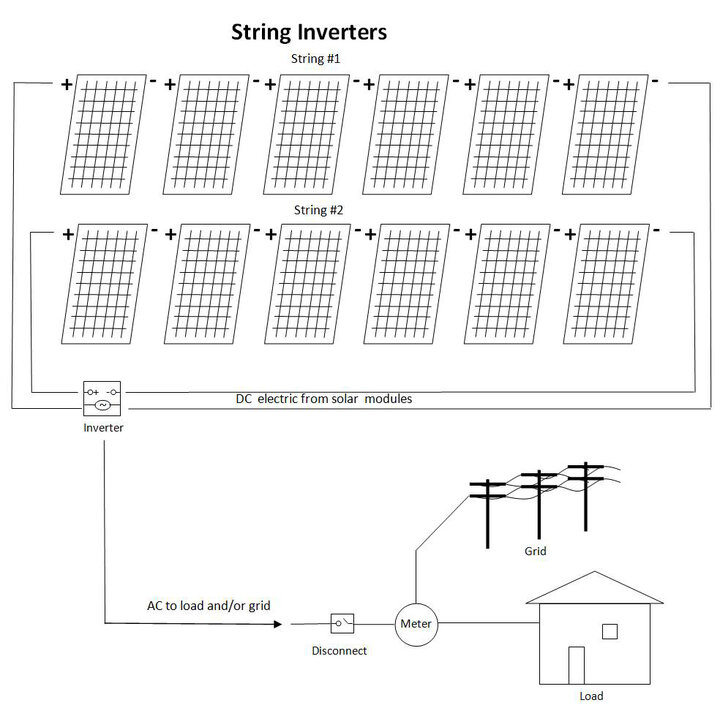

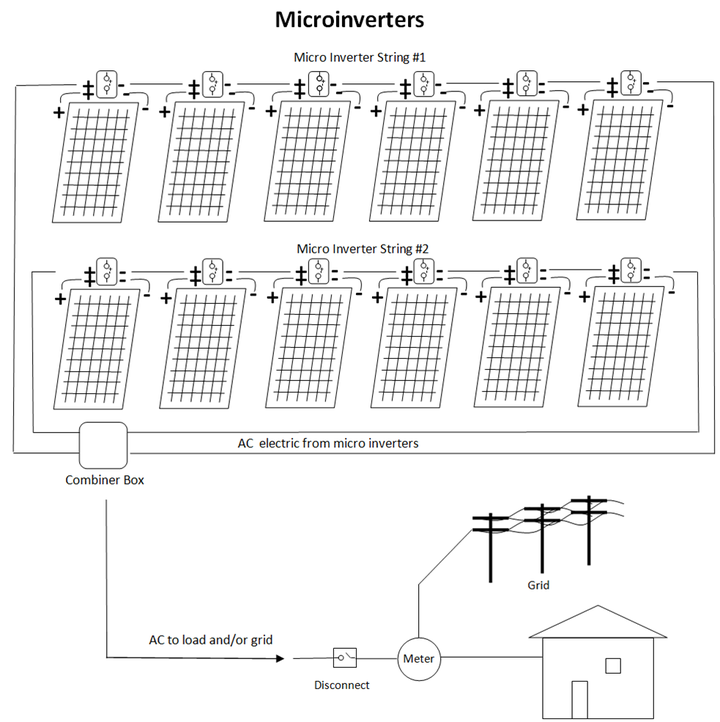

Three main inverter types exist. The combination of system siting, shade, and cost will determine which is best for each location.

String Inverters - best for ground mount applications with no shading (usually lowest cost, only array level monitoring, if roof mounted additional equipment may be needed to meet rapid shutdown requirements)

String Inverters with Optimizers - best for ground or roof mount applications, can improve performance in partial shade (middle cost, panel level monitoring, meets rapid shutdown requirements with no additional equipment)

Micro inverters - Best for roof mount applications, can improve performance in partial shade (usually higest cost, panel level monitoring, meets rapid shutdown requirements with no additional equipment)

Solar Mounting Systems

Another important aspect of a solar array is its mounting system. The mounting system plays an important role as it attaches the solar panels to their base, be it a roof, the ground, or a wall. The four common types of mounting systems are roof mount, pole mount, ground mount, and bracket mounting systems. The type of mounting system is usually chosen based on such factors as weather, site shading, base material, and orientation of the array.

Solar Cells

There are three main types of solar cells: monocrystalline, polycrystalline, and thin-film solar cells. Monocrystalline cells are made from a single large crystal of silicon, polycrystalline cells are made from an ingot made up of many smaller silicon crystals, and thin-film cells are made by transferring a thin film of silicon onto a steel sheet. Monocrystalline cells are traditionally most efficient while thin-film cells are least efficient, on average. Consider these things when selecting a solar module (panel). Solar cells assembleled into a solar panel. The industry calls a solar panel a solar module.

How solar PV cells turn sunlight into electricity: https://youtu.be/7g7Y2xoqZTU

Which solar modules (panels) should you select? Come common things to consider:

1. Astethics (these will be up for 20-30 or more years)

2. Cost (Cost per rated Watt). If space is not limited (large roof or ground mount) It may be much more cost effective to select a module with lower efficiency and lower cost per rated Watt than an expensive one with high efficiency.

3. Space, if space is limited selecting a high efficiency module may be important.

4. In all cases you what a quality module that will last for many years. Look at warranty, reviews and reputation of the modules you are interested in.

Contact:

John Hay

Extension Educator, Energy & Biofuels

(402) 472-0408

jhay2@unl.edu

Faculty Bio