Popcorn was grown on nearly 221,000 acres of land in the United States in 2017, the most recent USDA record. Nebraska, with 64,000 acres of popcorn, was the leading producer, accounting for 34% of US production with 368,000,000 pounds of the total 1 billion pounds produced that year. Other top producers are Illinois, Indiana, Iowa, Kansas, Kentucky, Michigan, Nebraska, and Ohio.

— USDA NASS 2017 Census of Agriculture

Popcorn, an important field crop for many producers in the Midwest, is not genetically modified. There is no herbicide-resistance to glyphosate, glufosinate, or 2,4-D as there is in field corn. As the number of herbicide-resistant weeds increases, it is even more important to use herbicides with multiple effective sites of action, to manage weeds in popcorn.

While there is considerable research on field corn and sweet corn sensitivity to herbicides, there is a lack of information on popcorn sensitivity to herbicides. Many herbicides labeled in field corn are not labeled in popcorn, are only labeled in yellow popcorn, or only labeled for a pre-emergence application in popcorn. There is a perception that popcorn is sensitive to some field corn herbicides and that white popcorn is more sensitive to herbicides than yellow popcorn (Loux et al., 2017).

To address this, a two-year study was conducted to evaluate weed control, crop growth, and yield response in Nebraska commercially available yellow and white popcorn hybrids treated with pre- and post-emergence herbicides labeled in yellow popcorn.

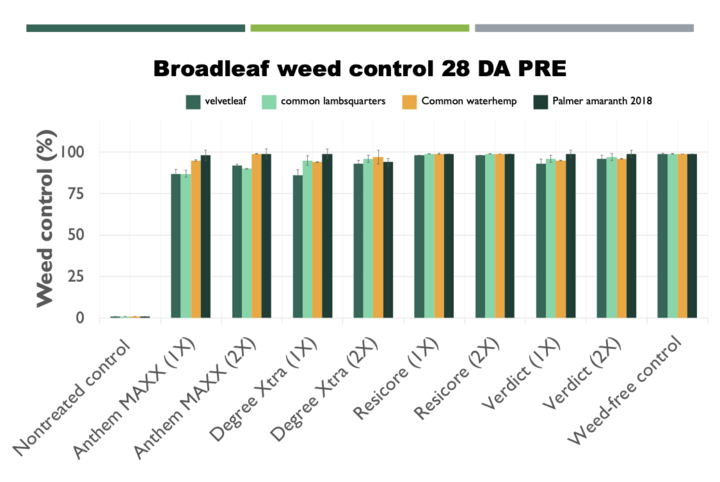

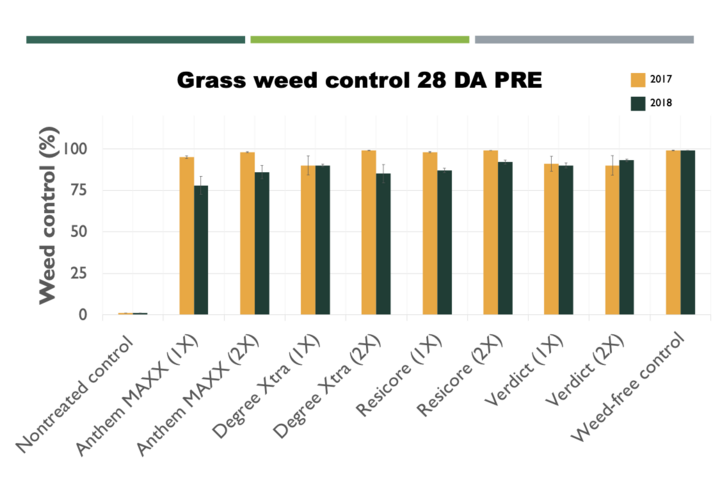

Field studies (Tables 1-2) were conducted in 2017 and 2018 at the University of Nebraska-Lincoln South Central Agricultural Laboratory near Clay Center with yellow and white popcorn hybrids commercially available in Nebraska. Herbicide programs provided excellent broadleaf weed control in popcorn (velvetleaf, common lambsquarters, common waterhemp, and Palmer amaranth). Only slight herbicide injury occurred in popcorn hybrids and it did not translate to measurable yield loss. Popcorn growers should read and follow herbicide labels as not all herbicides were used as labeled in this research.

Results

Eight popcorn hybrids were tested for herbicide sensitivity (Table 1). Four PRE and four POST herbicides were tested on the eight popcorn hybrids at a 1X rate (labeled rate) and 2X (twice the labeled rate). The 2X rate is for research purposes only and not approved on the label.

- Across all hybrids, PRE herbicide treatments resulted in 4-8% injury (100% = complete plant death).

- No herbicide injury was observed from POST herbicides applied in this study.

- The two white hybrids did not show greater injury than the six yellow hybrids.

- Weed control from PRE herbicides four to six weeks after treatment is summarized in Figures 1-6.

- At labeled rates, broadleaf weed control in both years ranged from 95% to 99% with all treatments three weeks after POST (100% = complete weed control).

- Foxtail control in 2017 ranged from 95% to 99% at three weeks after POST herbicide applied, but was limited (72%-86%) for most treatments in 2018.

- Yield losses ranged from 0% to 7% in herbicide treatments, with a 42% yield loss when weeds were allowed to compete without any herbicide application.

- Although slight hybrid differences in herbicide sensitivity were detected, the differences were not linked to popcorn color.

- Although this research suggests more herbicide options for popcorn growers, herbicide labels must still be followed.

References

Loux, M.M., D. Doohan, A.F. Dobbels, W.G. Johnson, B.G. Young, T.R. Legleiter, and A. Hager. 2017. 2017 Weed Control Guide for Ohio, Indiana, and Illinois. Pub# WS16 / Bulletin 789 / IL15. The Ohio State University.

US Department of Agriculture. National Agricultural Statistics Service, Washington, DC: U.S. Department of Agriculture. https://quickstats.nass.usda.gov/ Accessed July 30, 2019

| Hybrid | Kernel type | Supplier |

|---|---|---|

| M2101 | yellow | Conagra Brands, LLC, Chicago, IL 60654 |

| VYP315 | yellow | Conagra Brands, LLC, Chicago, IL 60654 |

| VYP220 | yellow | Conagra Brands, LLC, Chicago, IL 60654 |

| VWP111 | white | Conagra Brands, LLC, Chicago, IL 60654 |

| N1H820 | yellow | Zangger Popcorn Hybrids, North Loup, NE 68859 |

| R265 | yellow | Crookham Company, Caldwell, ID 83606 |

| SH3707W | white | Schlessman Seed Company, Milan, OH 44846 |

| AP2507 | yellow | Agricultural Alumni Seed Improvement Association, Inc, Romney, Indiana 47981 |

| Herbicide program | Relative rate* | Adjuvant§ | Label stipulations¶ | |

|---|---|---|---|---|

| 1 | Anthem MAXX (5 fl oz/acre) | 1x | None | None |

| Diflexx DUO (32 fl oz/acre) | 1x | COC | Contact seed provider or test in a small area first. | |

| 2 | Anthem MAXX (10 fl oz/acre) | 2x | None | None |

| Diflexx DUO (64 fl oz/acre) | 2x | COC | Contact seed provider or test in a small area first. | |

| 3 | Degree Xtra (3.7 qt/acre) | 1x | None | None |

| Solstice (3.15 fl oz/acre) | 1x | NIS | Yellow popcorn only; No UAN or AMS, use NIS; contact seed company, field man, or university specialist. | |

| 4 | Degree Xtra (7.4 qt/acre) | 2x | None | None |

| Solstice (6.3 fl oz/acre) | 2x | NIS | Yellow popcorn only; No UAN or AMS, use NIS; contact seed company, field man, or university specialist. | |

| 5 | Resicore (2.5 qt/acre) | 1x | None | Yellow popcorn only; PRE only |

| Armezon PRO (20 fl oz/acre) | 1x | MSO | Refer to seed company recommendations; 951 g ai ha‒1 maximum | |

| 6 | Resicore (5 qt/acre) | 2x | None | Yellow popcorn only; PRE only |

| Armezon PRO (40 fl oz/acre) | 2x | MSO | Refer to seed company recommendations; 951 g ai ha‒1 maximum | |

| 7 | Verdict (15 fl oz/acre) | 1x | None | Verify with supplier |

| Status (10 oz/acre) | 1x | NIS+AMS | Verify with supplier | |

| 8 | Verdict (30 fl oz/acre) | 2x | None | Verify with supplier |

| Status (20 oz/acre) | 2x | NIS+AMS | Verify with supplier | |

|

Abbreviations: AMS, ammonium sulfate (DSM Chemicals North America Inc., Augusta, GA); COC, crop oil concentrate (Agridex, Helena Chemical Co., Collierville, TN); PRE, pre-emergence; POST, post-emergence; MSO, methylated seed oil (Southern Ag Inc., Suwanee, GA); NIS, nonionic surfactant (Induce, Helena Chemical Co., Collierville, TN) |

||||