(At the author's invitation, changes were made to reflect Nebraska conditions.)

A killing frost is expected from Nebraska to North Dakota this weekend, which will end corn development in much of the Northern High Plains.

According to the U.S. Department of Agriculture’s National Agricultural Statistics Service, nearly 100% of the corn in Nebraska had reached full dent on October 6. Only 74% had reached maturity.

“It is important to check [the moisture content of] each field because these values will vary depending on planting date, corn maturity rating and growing degree days during the year,” Hellevang says. For the 18 states producing the majority of the corn in the U.S., only 58% of the corn was mature on Oct. 6. Across Midwest states, the percent mature ranged from only 22% in North Dakota and 52% in Iowa to 87% in Missouri.

The amount of drying in the field depends on parameters such as corn maturity, hybrid, moisture content, air temperature, relative humidity, solar radiation, and wind speed.

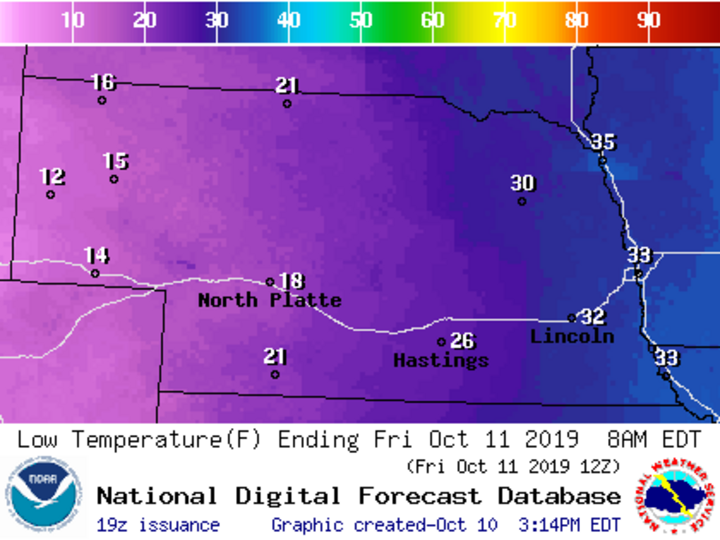

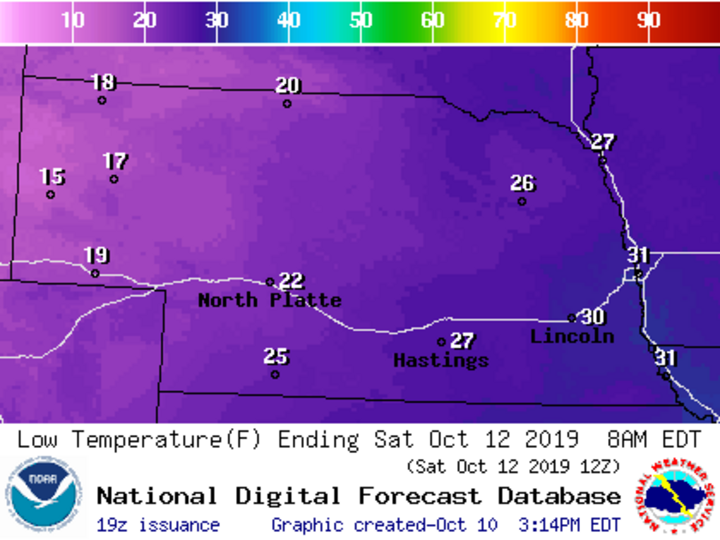

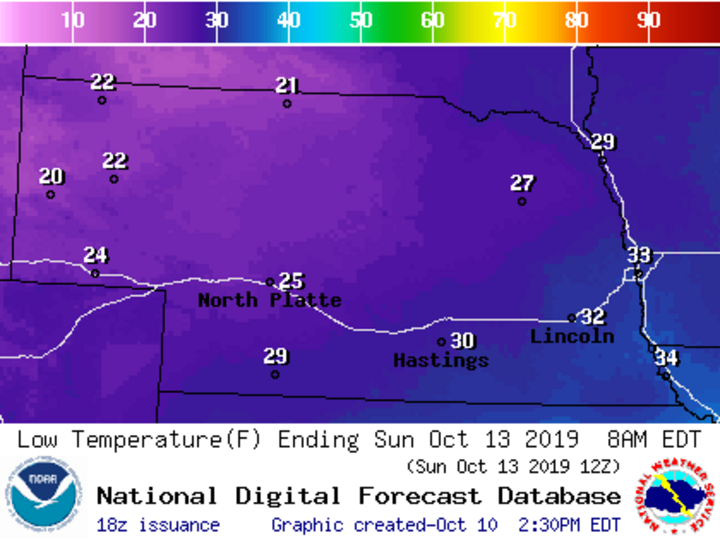

The current forecast is for the minimum temperature to be in the 20s or below in the western portion of the Dakotas and Nebraska on Oct. 11-12; Minnesota and Iowa are forecast to stay just above freezing. The Oct. 14-18 temperature is predicted to be much below normal across the Corn Belt, with a tendency for above-normal precipitation in some areas Oct. 16-22. (See Climatologist Al Dutcher's October forecast for Nebraska.)

“If these forecasts are accurate, the amount of field drying will be reduced,” Hellevang cautions.

Iowa State University has developed a Corn Dry Down Calculator that covers several Midwest states, including Nebraska. You select your location on a map and input estimated grain moisture content and the start of the dry-down period. For example, it estimates that if corn in south-central Nebraska is at 35% moisture on Oct.10, it will, on average, dry to about 22% by Oct. 30. (See this ISU Integrated Crop Management article for more information.)

Field drying normally is more economical until mid to late October in North Dakota and mechanical high-temperature drying normally is more economical after that, Hellevang notes. The midportion of the corn-producing states, including Nebraska, will have a more rapid field dry down due to the warmer temperatures. Natural-air drying also is more feasible there due to the warmer November temperatures, Hellevang said.

For example, corn reaching maturity in Nebraska on Oct. 11 is expected to dry in the field to about 21% on Oct. 30. The average November temperature in Nebraska is about 40°F, so air drying likely is feasible in November. However, with an airflow rate of 1 cfm/bu, drying may not be completed in November.

Corn field losses will depend on stalk strength, ear shank attachment to the stalk, winter conditions and wildlife. A September 27 story in CropWatch noted widespread stalk quality issues in Nebraska this year. Accumulated winter snow adds water to the soil as it melts. Plus, standing corn shades the ground, which reduces drying and may lead to wet fields in both the fall and spring.

Natural-air and low-temperature drying are limited to initial corn moisture contents of about 21%. Even at that moisture content, air drying is limited in the northern states due to the colder outdoor temperatures in late October and November.

The moisture-holding capacity of air is very small at temperatures below about 40°F. Expect to store the wet corn for the winter by cooling it to 20 to 30°F and finishing the drying in the spring when outside temperatures average above 40°F.

Provide an airflow rate of at least 1 cubic foot per minute per bushel (cfm/bu) to complete the drying before corn deterioration affects the market quality. The required fan size to provide the needed airflow can be determined using a fan selection program such as that developed by the University of Minnesota.

High-temperature corn drying may face challenges with high-moisture corn. The kernel color of immature corn may be affected during drying due to sugars still being in the kernel. Hellevang recommended reducing the dryer temperature to reduce the potential for affecting the kernel for corn that was not mature at the time of the first hard freeze.

Hellevang also warns that corn at moisture contents above about 23% may have enough surface moisture on the kernels that the kernels freeze together in the bin and will not flow.

For more information on grain drying and storage see the Grain Storage Management section of CropWatch, the NDSU Grain Drying and Storage website, or the Grain Storage tag linking to grain storage news articles in CropWatch.