Combines are very good at what they do, namely separating seeds from plants during the harvest process. Unfortunately, this can include separating weed seeds from weeds in the field. As a result, combines can spread weed seeds directly from the back of the combine or carry weed seeds to new areas, resulting in weed escapes.

Weed Seed Introductions

Weeds can enter and establish in fields in a number of ways. Some weeds may be introduced by wildlife, wind or water and can be transported dozens of feet or even miles.

Another method of seed transport is human activity. Weeds can become attached to vehicles, which then spread seeds along roadways or into fields. Weed seeds are also commonly transported on agricultural equipment, such as tractors or tillage implements, through soil attached to machines or by carrying plant material.

As the prevalence of resistant and hard-to-manage weeds such as Palmer amaranth and common waterhemp increases, the need for weed management tools in addition to herbicide is increasingly important. These weeds are known to produce as many as 500,000 seed per plant so preventing their spread within a field or across a farm will help manage these difficult weed species.

How Combines Spread Weeds

Combines spread weeds primarily in two ways. One way is spreading weed seeds within individual fields. This has the potential to make an isolated weed problem, such as an individual plant, a fieldwide issue in only a handful of seasons. Another way that combines can spread weed seeds is by transporting them between fields, introducing weeds to new areas of the farm.

No matter how weeds initially get established within a field, combines are very efficient spreaders as many of our common agronomic weed species do not shatter and remain on the plant until harvest or some other physical separation. In addition to harvesting crop, they can also harvest weeds if they’re present in the field, thresh their seeds, and distribute the seeds. The seeds will mainly be expelled from the back of the combine with the chaff and residue, creating linear patches of weeds the next season (Figure 2).

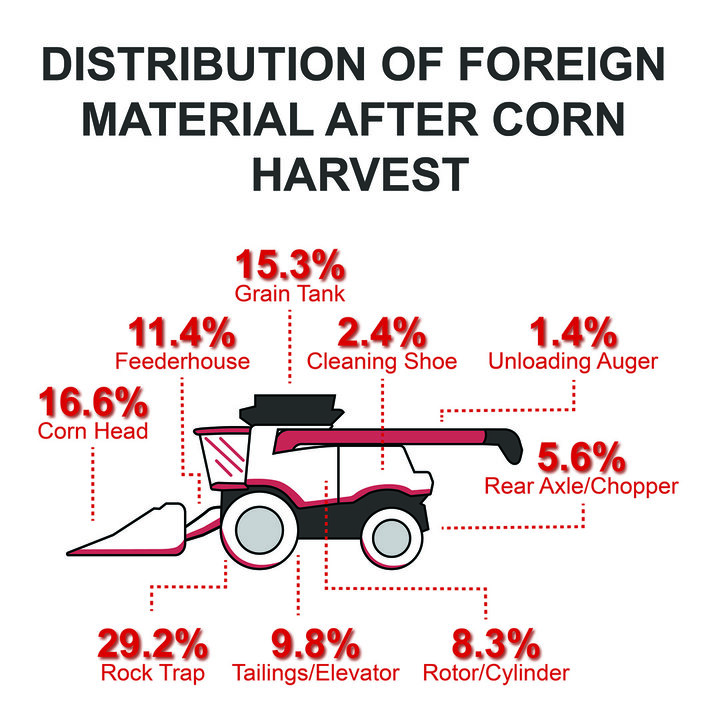

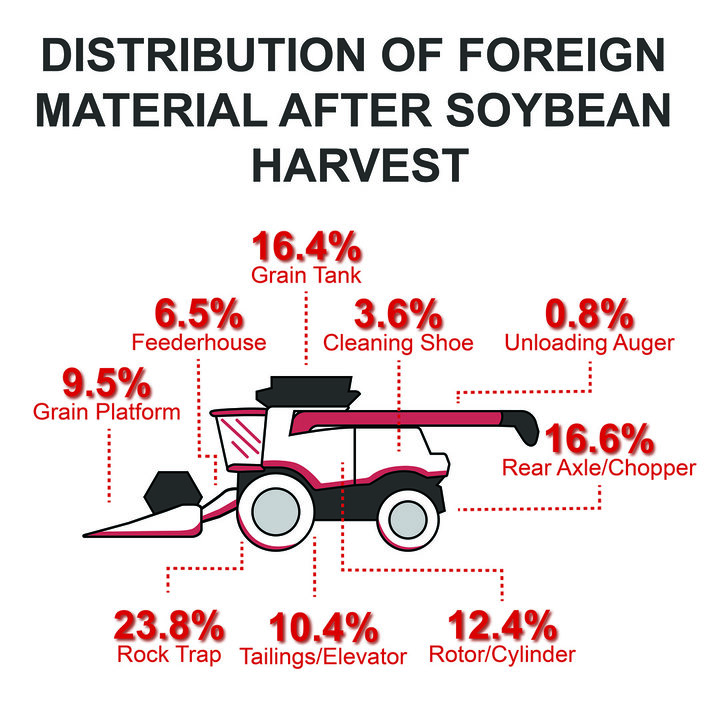

However, a study conducted at Iowa State University showed that significant amounts of foreign material — which could include weed seeds — accumulate in different parts of the machine (Hanna et al., 2009). These data show the relative percentage of material in different areas of the combine following corn and soybean harvest (Figures 3-4).

The results of this study show that a significant amount of material can accumulate in some areas of the combine, such as the rock trap, rotor/cylinder, grain tank and tailings elevator. However, weed seeds in these areas may not be the largest concern, as they are largely held in these areas and not distributed. The largest concern may be the foreign material and therefore, weed seeds that may accumulate on the grain platform or corn head and feederhouse. Weed seeds in these locations can spread within fields but also to new fields as combines move to harvest grain throughout the farm. Fortunately, these areas are relatively easy to access and can be cleaned quickly.

Where Weeds Hide in a Combine

In response to the Iowa study on distribution of foreign material, a 2020 Wisconsin study by Dr. Rodrigo Werle and Nick Arneson went a step further to quantify weed seeds on a combine and found that the majority of weed seeds contained in a combine are found on the head/platform, rocktrap and feederhouse. The rotor contained a minor percentage of weed seeds. These results can provide additional guidance on where to focus when cleaning a combine for weed seeds and how much time to dedicate to combine cleaning for weed seeds.

Cleaning a Combine to Prevent Weed Seed Distribution

Combine cleaning is a relatively simple management practice that can save a significant amount of time, money and headache in the future. In as little as 20-30 minutes, the main areas of the combine that often hold weed seeds can be cleaned.

It’s recommended that these areas be inspected and cleaned at a minimum prior using a pre-owned combine for the first time on your farm, before harvest, after combining weedy fields or very weedy areas of a field, and at the end of harvest. A full combine cleaning to identify persevered grain or end-of-season clean-out for maintenance is much more involved process and will take more time.

When cleaning a combine, make sure that the combine is in a safe area where weed seeds can fall on the ground and not be an issue, such as the field where the machine harvested last or back at the farm shop. Also be sure to wear appropriate personal protective equipment (PPE) and read the owner’s manuals, particularly sections about cleaning and equipment safety.

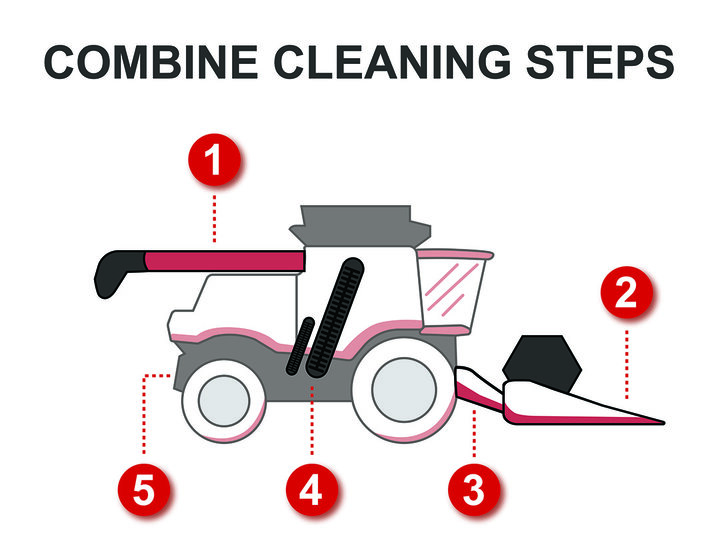

To complete a quick clean-out of the combine, follow these procedures and reference Figure 5.

- Run the unloading auger to ensure that it’s empty.

- Working from the front of the combine, blow out the corn head or soybean draper. One of the best tools for cleaning the combine is a leaf blower or air compressor. When blowing out the machine, look for areas where residue naturally accumulates, such as under the corn snouts.

- Clean the feederhouse, again looking for areas where residue may have accumulated. While at the front of the machine, open the rock trap and allow any material that’s been collected to fall out.

- Moving to the side of the machine, open the tailings return, clean grain elevator, and unloading auger sump and allow any trapped residue to escape.

- Once the previous steps are complete, do a full lap of the exterior, using a leaf blower or air compressor to clean any surfaces where residue may have accumulated, such as on the axles and residue management system.

- Lastly, close the access panels that were opened earlier.

Conclusion

While it can be daunting to add another task during harvest, in as little as 20-30 minutes and with the proper equipment and safety precautions, a combine can be cleaned to reduce the chances of transporting weed seeds to the next field or farm. This will reduce the number of headaches for future seasons by reducing weed introductions and distribution, therefore reducing costs for herbicides and improving crop quality.

Helpful Resources

Weed Seed Movement via Combines Case Study

Weed Seed Management at Crop Harvest

Video: Combine Cleaning to Prevent Spreading Weeds

References

Hanna, H.M., Jarboe, D.H., Quick, G.R. (2009). Grain residuals and time requirements for combine cleaning. Applied Engineering in Agriculture, 25(6), 851-861. doi: 10.13031/2013.29231