While the North American Manure Expo may not reach bucket level status in your vacation plans, for anyone replacing or upgrading equipment for managing manure, it is the place to be. Manure handling equipment on display at the 2019 Manure Expo in Fair Oaks, Indiana in August continues to target the themes of bigger, faster, and further. However, one emerging theme common at this year’s Manure Expo was “Precision Manure.” This article will share a few observations around my conversations with vendors and manure applicators on “Precision Manure.” Mentions of specific products and companies are not intended as an endorsement, only as an example of available technology.

Farmer and Commercial Applicator Experiences

The Manure Expo included several panels and presentations by farmers and commercial applicators. Here are a few precision themes that were shared by multiple presenters:

- Precision is the Future. Every commercial applicator identified several precision technologies that are currently part of their business. Scales or flow meters paired with the vehicle’s GPS technology were used by all commercial applicators for several services. John Deere’s nutrient sensor (discussed next) was part of the immediate plans of two commercial applicators applying slurry/liquid manures.

- Uniformity. Precision technology paired with well-designed application equipment was highlighted as essential to the desired uniformity to treat manure as fertilizer.

- Application and restricted area maps are now an essential service of all commercial applicators. Coupling restricted-area, map-based control with GPS systems can automatically eliminate the potential for manure application in environmentally sensitive areas.

- Value. Manure delivers 25 to 30 bushels of corn per acre added production due to its fertility and soil-building benefits according to one Indiana crop farmer panelist. Multiple testimonials of the value of manure to both traditional and organic crop production were shared by every farmer and applicator panelist.

John Deere Manure Sensor

The Expo provided my first opportunity to see technology for monitoring slurry and liquid manure nutrient concentration on-the-go. The Manure Constituent Sensing unit (Figure 2) by John Deere is based on Near Infrared (NIR) technology calibrated for use with manure. This same technology is used with mobile feed nutrient analysis.

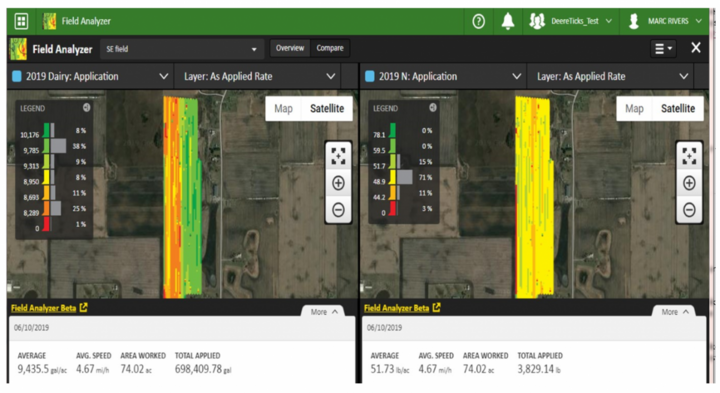

The John Deere manure sensor, when combined with a flow meter, can deliver site-specific documentation of application rates of total ammonium nitrogen, phosphorus, potassium, and total solids. The user can define and apply the desired target rate for a limiting nutrient. The NIR sensor and flow meter provide the key inputs for controlling tractor speed to achieve a desired nutrient application rate. For additional precision, a GIS software package can be used to create site-specific maps (Figure 3) for manure application or contribute key information to later fertilizer application variable rate planning.

As-Applied Maps

Any manure applicator knows that managing manure as a fertilizer requires uniform application of a consistent product. While the consistent product is an ongoing challenge, the uniform application is a common theme shared by equipment dealers. The addition of weigh scales (or flow meters) to document application rate in combination with the vehicle’s GPS technology was a common option with all equipment suppliers I met at the Expo. Digital maps similar to the left map in Figure 3 (gallons manure/acre) were available from all equipment suppliers with whom I visited. Digital “as-applied” maps are an option for all of us (assuming the check book’s balance does not object!).

Why are such maps important to a manure applicator in 2019? Here are a few of the obvious answers I heard:

- Valuable documentation for the regulatory community of application rates, timing relative to rainfall events, and setbacks maintained.

- A valuable tool for preventing application on sensitive areas such as required setbacks from surface and groundwater connections. By electronically establishing application boundaries and turning manure application off outside these boundaries, regulatory compliance and being a good neighbor just became easier.

- Excellent planning tool for those making fertility decisions. What locations are lacking or short on manure nutrients? This is important input to nutrient fertility planning and site-specific mapping decisions for variable-rate fertilizer application to complement the manure’s fertility. Complimentary benefits of manure and fertilizer can lead to greater yields. See Does Manure Benefit Crop Productivity? Environment? for additional information.

- Am I overlapping manure applications or applying too much manure on some areas of the field. With GPS guidance systems, this should be much less of an issue. But the maps give a manure applicator one additional check. With manure often offering a fertility value measured in terms of hundreds of dollars per acre, over-application does not make sense.

Many vendors also shared the importance of these same technologies for contributing to on-the-go spreader or tractor adjustments to create more uniform manure application rates or to adjust manure application rates based on site-specific maps for meeting variable fertility needs.

What Are Your Precision Manure Experiences?

Who is willing to share field experience with precision manure management technologies? What technologies are you finding most valuable? What are the challenges you are encountering? If you are willing to share those experiences, I (rkoelsch1@unl.edu) would welcome learning more from you. Thank you.