Here's How to Address Them

The new phenoxy herbicide formulations, including Enlist Duo™ (Dow), XtendiMax® (Monsanto), Engenia™ (BASF), and FeXapan™ (DuPont), offer growers new management options along with new application requirements. XtendiMax, Engenia and FeXapan are dicamba-based herbicides. XtendiMax and FeXapan are identical and use “VaporGrip®” technology to reduce volatility. Engenia uses a new dicamba salt to reduce volatility.

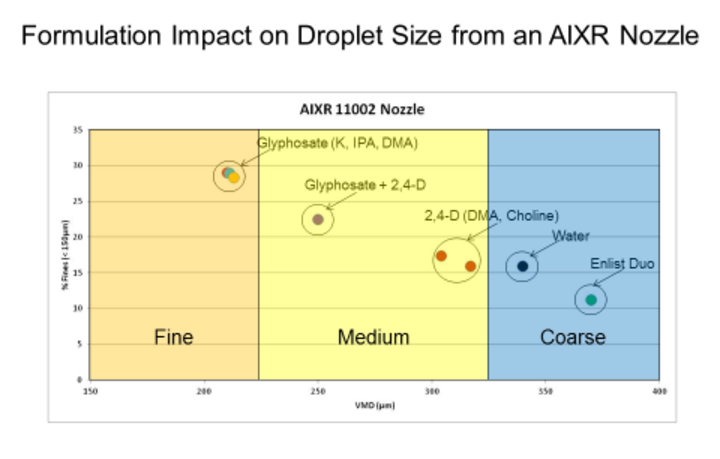

Enlist Duo herbicide has Colex-D technology and combines a new 2,4-D choline and glyphosate, which provides drift reduction in addition to 96% less volatility than 2,4-D ester. Figure 1 illustrates the formulation impact on droplet size from an AIXR nozzle. Limited amounts of Enlist soybeans are being planted for seedstock and sprayed.In the past we have experienced problems when crops resistant to a particular herbicide were commercialized. For example, when Roundup Ready soybean came to the market in 1996, there were a number of problems with spray drift, primarily to corn. Better application practices, including spray nozzle selection, were successful in minimizing the application problems.

To alleviate problems related to applying new phenoxy herbicide formulations in soybeans as well as to increase herbicide performance, manufacturers have established application requirements. Here we discuss some of the key application factors to consider.

- additives,

- herbicide rate,

- spray volume,

- nozzles,

- spray boom height,

- weed height,

- wind speed, and

- ground speed.

Check the herbicide label to make sure your application meets the requirements as changes may occur after publication of this article.

Additives

Many additives such as AMS, drift retardants, etc., are prohibited from being mixed with new dicamba formulations. This is because many of these additives reduce spray droplet size and increase the number of fines. With one nozzle type, the spray droplet size was reduced to about 60% when glyphosate and AMS were mixed as compared to the droplet size with water. Also, fine small spray droplets under 105 microns increased by four times (4X).

Herbicide Rate

It is important to use the labeled application rate to control the weeds and to reduce the chance of selection pressure due to sub-lethal dose. The old saying is “dead weeds don’t produce seeds.” Additionally, the active amount of dicamba varies from product to product. For example, XtendiMax has 2.9 lb acid equivalent per gallon compared with Engenia which has 5 lb acid equivalent per gallon. Therefore, each product has a different application rate.

Spray Volume

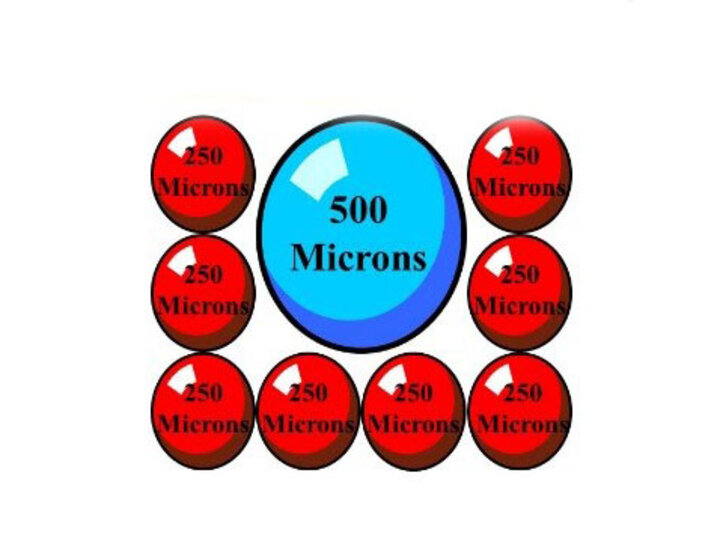

To reduce spray droplet drift with new phenoxy herbicide formulations, the required nozzles and pressures listed on product labels produce large spray droplets. These large droplets reduce coverage. For example when you double the size of the spray droplet from 250 to 500 microns in diameter, you apply one-eighth the number of spray droplets that you would have previously (Figure 2).

For example a number 2 pencil is 2000 microns in diameter. A 1,000-micron spray droplet that has 12 droplets per square inch would not provide much coverage at 10 gallons per acre (Table 1).

Spray nozzles provide various spray droplet sizes. We list the VMD (Volume Median Diameter), which means it will include both smaller and larger spray droplets than the size listed. Smaller droplets increase coverage while larger ones reduce coverage.

The number can also be somewhat misleading as the droplets per square inch represent coverage on a flat surface. In applying pesticides to plants or weeds, we can have many times the surface area to cover compared to spraying a flat surface. An old standard was you could apply up to 100 GPA before you would have run-off of the plants or weeds.

Many of the nozzles and pressures listed in the application requirements produce spray droplets in the ultra coarse category or approximately 665 microns or greater in size. It may be advisable to consider increasing the spray volume above the required minimum to increase coverage. Coverage is especially important with smaller weeds and dense canopies. This can be a negative when applying some herbicides with reduced concentrations such as glyphosate.

Recently a farmer bought a new sprayer and because of weather conditions hired an aerial applicator to provide timely herbicide application. He noted that the aerial applicator got better weed control than he did with his new sprayer. This was because the farmer used a nozzle that provided a very large spray droplet (which reduces spray droplet drift) but didn’t adjust the spray volume to get the coverage needed. If he had increased the spray volume, he probably would have had similar results as the aerial applicator.

| Droplet Diameter (Microns) | Droplets per in2 at 10 GPA |

|---|---|

| 200 | 1445 |

| 500 | 90 |

| 1000 | 12 |

Nozzles

Table 2 illustrates how the various spray droplet sizes affect percent area coverage and deposition.

The spray nozzle tip is important because it:

- controls the amount applied – GPA;

- determines the uniformity of application;

- affects the coverage;

- affects the spray drift potential;

- breaks the mix into droplets;

- forms the spray pattern; and

- propels the droplets in the proper direction.

| Nozzle | Pressure | VMD (DV0.5) | % Area Coverage | Deposition (GPA) |

|---|---|---|---|---|

| XR 11003 | 28 | 372 | 17.4 | 7.0 |

| TT 110025 | 40 | 391 | 15.1 | 5.9 |

| TTI 11002 | 70 | 540 | 10.7 | 3.8 |

| *Comparison of spray droplet size and coverage for nozzles used for agronomic weed control. Robert E. Wolf, associate professor and application technology specialist, Kansas State University | ||||

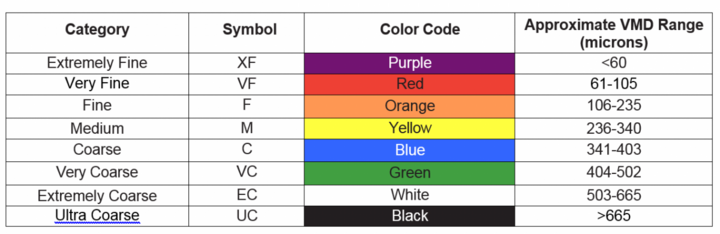

The American Society of Agricultural and Biological Engineers (ASABE) developed a droplet size classification system (ASABE S-572.1) that ranges from extremely fine to ultra coarse, based on DV values measured in microns (Figure 3). The droplet size category recommended for use with a particular pesticide may be listed on the product label.

Figure 3. Color codes for droplet size and approximate volume median diameter (VMD). (Source: ASABE S572.1)

Nozzle selection and pressure can then be based on the nozzle manufacturer’s droplet size category charts. Typically, low-drift nozzles will produce spray droplets in the coarse to ultra coarse range, reducing the number of fine droplets likely to drift.

Because of differences in the equipment and methods used to measure droplet sizes, different nozzle manufacturers may report different micron values for ASABE S-572.1 droplet size categories. Droplet sizes are calibrated against a reference nozzle and pressure for each droplet category, so even though two nozzles may report a different micron value for their VMD (also known as DV0.5), both will produce a “coarse” category droplet of the same size.

The nozzles and pressures approved for applying these herbicides give larger spray droplets and reduce the number of fines to manage spray droplet drift. See the product label for approved nozzles and pressures to be used with various nozzles.

Spray Boom Height

Boom height is the second factor in spray droplet drift. When you double the boom height from 18 to 36 inches, you increase the amount of spray droplet drift at 90 feet from the sprayer by 350%. Table 3 shows the effect of increasing the boom height from 2 to 3 feet for various spray droplet sizes and two wind speeds. Remember, even if you use a nozzle and pressure that produce an ultra coarse spray droplet size, you will still have some small spray droplets.

| Initial Droplet Size (micron) |

Wind Velocity (mph) |

Drift Distances (ft) with 2-Foot Nozzle Height |

Drift Distances (ft) with 3-Foot Nozzle Height |

| 50 | 4 | 23.80* | 23.98* |

| 50 | 10 | 52.89* | 53.43* |

| 150 | 4 | 3.57 | 7.49 |

| 150 | 10 | 8.92 | 18.75 |

| 300 | 4 | 0.24 | 0.79 |

| 300 | 10 | 1.04 | 1.97 |

| * Droplet completely evaporated before deposition. | |||

Weed Height

Research has shown that smaller weeds are easier to control. Also, crop yields are reduced more as the crop competes with weeds for space, nutrients, soil water, and light. Large weeds may also affect coverage by preventing spray from reaching all the weeds in the canopy.

Wind Speed, Temperature Inversions, and Downwind Buffers

Wind is the number one factor in spray droplet drift. Doubling the wind speed from 5 to 10 or 10 to 20 mph results in seven times more spray droplet drift 90 feet from the sprayer. Check the product label for application requirements relative to wind speed.

Windless conditions also can create a problem. Winds of zero to 3 miles per hour may indicate a temperature inversion (see box). In this circumstance, it’s difficult to determine where the drift will end up.

How to Avoid Applications during Temperature Inversions

In the past, scientists have pegged fog, dew, or frost as signs of a temperature inversion. However, these are characteristic of morning hours, when temperature inversions are usually breaking up for the day. Based on the new data from Missouri, applicators and growers need to be on alert for clear, windless evenings.

When the wind dies down on a clear night, that's when it's time to stop spraying. Other signs include dust or smoke hanging low or moving laterally in the air.

The labels of two new dicamba herbicides — Monsanto's XtendiMax and BASF's Engenia — instruct applicators not to spray during a temperature inversion. The Engenia label requires growers to check for wind speeds below 3 mph, while the XtendiMax label forbids spraying when winds are below 3 mph.

What's a Temperature Inversion?

As the sun heats the ground during the day, warm air rises and is replaced by cooler air, which in turn warms and rises. This continual motion keeps air moving near the ground, producing wind. Sometimes, on very clear days, the air can become dangerously still. This happens most often as the sun sets and the ground cools and air stops rising, resulting in a stable, stationary air mass hanging just above the ground.

When growers spray during these conditions, the spray droplets cannot fall to the ground and instead hang, suspended in that air mass, until the inversion ends and wind arrives to move them — possibly off-target. These conditions can be detected by measuring air temperatures at different heights. During a temperature inversion, the temperature near the ground will be cooler than the air above it.

For two years, University of Missouri researchers have been measuring temperature at three heights every five minutes at three Missouri locations. The results have been eye-opening.

From March to July in both years, inversions occurred at least half of the evenings. In the early part of season, the inversions mostly occurred between 5 p.m. and 6 p.m.; in June and July they tended to occur between 6 p.m. and 8 p.m. The research showed that low wind speeds (less than 3 mph) in the evening in June and July predicted the beginning of an inversion 90% of the time.

Susceptible Crops

The required downwind buffer is listed on the label to help protect sensitive areas. Herbicide applications shouldn’t be made when the wind is blowing toward adjacent susceptible crops as it takes only a small amount of herbicide to cause major injury or even death of susceptible crops. (See Tables 4-6.)

If conditions are not appropriate for spraying, don’t spray or only spray the part of the field where it will be safe and come back another day when the wind direction has changed to finish spraying the field.

Table 4 has the injury level for three rates of dicamba for dicamba-tolerant DT-soybean, conventional soybeans, grapes, and tomatoes.

Table 5 has the injury and yields for three levels of dicamba on dicamba-tolerant soybeans, Roundup Ready soybeans, and conventional soybeans applied at the V2 vegetative growth stage.

Table 6 has the same information as Table 5 except dicamba was applied at the full flower (R2) growth stage.

Tables 4-6 all reflect preliminary data from a study conducted by Nebraska Extension Weed Specialist Stevan Knezevic. They are based on simulated rather than actual “off target” studies. The studies are being continued in 2017 and 2018 and results will be reported at the study’s conclusion.

| 1/10* (1.6 oz) | 1/100* (0.16 oz) 1 teaspoon | 1/500* (0.032 oz) 1/5 teaspoon | ||||

|---|---|---|---|---|---|---|

| V2 | R2 | V2 | R2 | V2 | R2 | |

| DT-Soy | 0 | 0 | 0 | 0 | 0 | 0 |

| Conventional Soy | 75 | 42 | 44 | 21 | 41 | 13 |

| Grapes | 100 | 20 | 28 | 9 | 20 | 8 |

| Tomato | 73 | 56 | 23 | 23 | 15 | 23 |

| *Of full application rate per acre (16 oz) Source: Preliminary data from Stevan Knezevic Simulated Drift Study, UNL V2 = 2nd trifoliate |

||||||

| Rates (oz/ac) |

Rates (oz/ac) |

DT-soy % |

DT Soy bu/ac |

RR Soy % |

RR Soy bu/ac |

Conven. Soy % |

Conven. Soy bu/ac |

| 0 | -- | -- | 75 | -- | 77 | -- | 75 |

| 1/10* | 1.6 | 0 | 75 | 72 | 45 | 75 | 41 |

| 1/100* (1 tsp) | 0.16 | 0 | 73 | 32 | 70 | 44 | 65 |

| 1/500* (1/5 tsp) | 0.032 | 0 | 74 | 34 | 71 | 41 | 68 |

|

*Of full application rate per acre (16 oz) |

|||||||

| Rates (oz/a) |

Rates (oz/a) |

DT Soy % |

DT Soy bu/ac |

RR Soy % |

RR Soy bu/ac |

Conven. Soy % |

Conven. Soy bu/ac |

| 0 | -- | -- | 71 | -- | 78 | -- | 70 |

| 1/10* | 1.6 | 0 | 71 | 42 | 19 | 42 | 15 |

| 1/100* (1 tsp) | 0.16 | 0 | 72 | 32 | 66 | 21 | 58 |

| 1/500* (1/5 tsp) | 0.032 | 0 | 72 | 34 | 75 | 13 | 73 |

| *Of full application rate per acre (16 oz) Source: Preliminary data from Stevan Knezevic Simulated Drift Study, UNL |

|||||||

Ground Speed

Most labels for these herbicides contain limits on the maximum ground speed for the sprayer. High speeds contribute to more spray boom bouncing, make it difficult to control boom height, creating more dust, and distorting the spray pattern.

Boom height controllers usually do not do as good a job at speeds above 14-15 mph as they do at lesser speeds. (The 2017 Guide for Weed, Disease and Insect Management in Nebraska includes tables for application speeds up to 14 mph.)

Closing Recommendation

Again, always check for the latest label information before applying pesticides. These labels help increase pesticide efficacy and spray drift management. The label is also the law.

Resources

- ASABE Standard S572.1 Spray Nozzle Classification by Droplet Spectra

- Droplet Size Classification Quick Guide

- The 2017 Guide for Weed, Disease and Insect Management in Nebraska offers several sections on sprayerset-up and applications.

- Cleaning Pesticide Application Equipment, Nebraska Extension NebGuide G1770

Thorough Cleaning of the Sprayer

It is always important to do a good job of cleaning the sprayer to avoid pesticide contamination, but it is especially important with these products because even a small amount of residual herbicide can cause serious damage. See Nebraska Extension NebGuide Cleaning Pesticide Application Equipment (G1770) for proper procedures. Many tank, boom, etc., cleaners work better if left in the sprayer overnight.

Tables 4-6 illustrate how just a little dicamba can cause major injury or death to susceptible crops. In one example a sprayer was used on Friday afternoon to spray three loads of Roundup on Roundup soybeans. A fourth load was ready to be sprayed and, because of rain, sat in the sprayer all weekend. When the spraying began on Monday afternoon, there was major injury to the soybeans. The Roundup and additives that set in the sprayer all weekend did a good job of cleaning the booms and sprayer tank, breaking down herbicide residue from earlier in the week.