March 30, 2007

(With warm temperatures bringing early weeds, the following story is being reprinted from the May 26, 2006 CropWatch to aid with pesticide application safety.)

Pesticide drift is usually a lose-lose situation. The first loss is the damage the drift may cause to an off-target area such as susceptible vegetation, water supplies and wildlife. The second loss is incurred by the original target, which receives less than the intended amount of pesticide. To avoid problems, always read and follow pesticide label recommendations for drift management. Surveys indicate that about two-thirds of drift complaints derive from applications known to be off-label.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

There are two kinds of spray drift — vapor drift and particle drift.

Vapor drift is the volatilization of pesticide molecules and their movement off-target. It occurs independently from the application. The potential for vapor drift of any pesticide can be predicted by its vapor pressure, the air temperature, size of treated area and climatic conditions. Vapor drift can travel much further than particle drift. Avoid vapor drift by not using pesticide formulations whose potential volatility is high, given the air temperature and climatic conditions. These include pesticides which will volatilize rapidly from moist soil or higher temperatures (see Table 1). Particle drift is the off-target movement of spray particles formed during application. It is affected by the environment, application equipment, and how the equipment is used. Spray particles less than 200 microns can drift considerable distances. Large spray particles may reduce drift, but may not provide the coverage needed.

Spray droplet sizes

Agricultural spray nozzles produce a wide range of spray droplet sizes - from10 to more than 1000 microns. As a comparison, a pencil lead is approximately 2000 microns in diameter. A paper clip wire is 850 microns, a staple wire is 420 microns, a toothbrush bristle is 300 microns, a sewing thread is 150 microns, and a human hair is approximately 100 microns in diameter.

The key is to set up the sprayer to produce the largest droplets that will provide adequate control of the target pest. This is a balancing act between the particle size that is best for drift control and the one that is best for product efficacy. In some situations, efficacy may have to be sacrificed to avoid drift.

|

| Figure 1. Normal temperature profile — temperature decreases with height. |

|

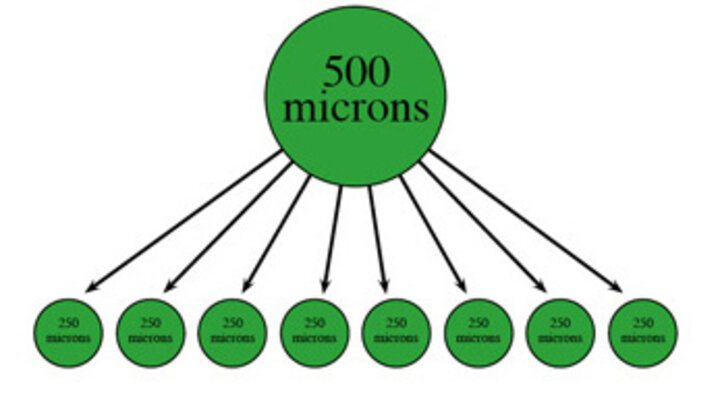

| Figure 3. Cutting droplet size in half results in eight times the number of droplets. |

The drift potential depends not only on the volume medium diameter (VMD), but also the total spectrum of droplet size. A VMD of 300 could mean that half the droplets were 250 microns in diameter and half were 350 microns. Or it could mean half the droplets were 50 microns (very susceptible to drift) and half were 650 microns. The VMD plus the droplet spectrum gives a more accurate estimate of the droplet size relative to drift. If you double the droplet size you have 1/8 as many spray droplets (see Figure 1). Spray droplets leave the nozzle at a certain speed. Small droplets (less than 200 microns), lose momentum faster than large particles and slow to the fall of gravity; when slowed by other forces such as air movement.

Big 3 in spray drift management

Dave Smith, a Mississippi State University ag engineer, analyzed data for more than 100 studies involving drift from ground sprayers. Of the 16 variables he considered, three were the most important: wind speed, boom height, and distance downwind.

Wind speed. When the wind speed was doubled, there was almost a 700% increase in drift when the readings were taken 90 feet downwind from the sprayer. Hence the recommendations of spraying in 10 mph wind or less. Be aware that drift potential also may be high at low wind speeds. This is because light winds (0-3 mph) tend to be unpredictable and variable in direction. Calm or low wind conditions may indicate the presence of a temperature inversion. Drift potential is actually lowest at wind speeds of 3 to 10 mph (gentle but steady breeze) blowing away from sensitive areas.

Boom height. When the boom height is doubled, for example from 24 to 48 inches, the amount of drift increased 350% at 90 feet downwind.

Distance downwind. If the distance downwind is doubled, the amount of drift decreases five-fold. If the distance downwind goes from 100 to 200 feet, you have only 20% as much drift. If the distance goes to 400 feet, you only have 4% of the drift you had at 100 feet. Check wind direction and speed when starting to spray a field. You may want to start spraying one side of the field when the wind is lower or you may choose to only spray part of a field because of wind speed, wind direction or distance to susceptible vegetation. The rest of the field can be sprayed when conditions change.

Reducing drift in susceptible areas

Also consider slowing down on the passes closest to susceptible vegetation, etc. If you slow from 10 mph to 7 mph (70% of the speed) and are spraying at 40 psi with a rate controller, your pressure will drop by one-half to 20 psi (Table 2). You also can make these changes manually, but be careful to not drop below the minimum recommended pressure for the nozzle tip being used. You also can lower the boom when travel speed is reduced. Other important factors to consider when trying to reduce drift include spray pressure, nozzle size, nozzle orientation, operating speed, air temperature, relative humidity, shields on sprayers and nozzles, application rate and instructions from the manufacturer of the spray product. Temperature and vapor pressure during a herbicide application also influence drift.

Effects of temperature inversions

Atmospheric stability is an important factor that is often ignored. Temperature inversions occur when a layer of cool air near the soil surface is trapped under a layer of warmer air (see Figures 2 and 3). With temperature inversions, the temperature increases as you move upward. This prevents air from mixing with the air above it and causes small-suspended droplets to form a concentrated cloud that can move long distances. If large numbers of small droplets are captured in this warm or inversion layer, the deposition control is lost. Records indicate that movement of these inversion layers may transport chemicals several miles.

|

It's important to recognize when inversions are present. Bodies of water or well-irrigated fields favor the formation of inversions. Under clear to partly cloudy skies and light winds, a surface inversion can form as the sun sets. Under these conditions a surface inversion will continue into the morning until the sun begins to heat the ground. Usually if you wait for a 5-degree increase in temperature after sun up, the chance of an inversion decreases greatly. Inversions only affect the small pesticide droplets that don't settle quickly. There is a higher potential drift and therefore off-target effects if the application is made during a surface inversion. The small droplets can remain in a concentrated cloud until the inversion dissipates or the cloud of droplets moves out of the area where inversion conditions exist. Minimizing the production of small droplets will minimize the potential or drift under inversion conditions. It may be illegal to start a fire to determine the presence of an inversion or wind direction. Instead smoke bombs or smoke generators are recommended.

Drift reduction nozzles

Many new spray nozzles are designed to reduce drift. Many of these use a pre-orifice which controls flow rate. The exit orifice controls the pattern formation. The result is larger spray droplets which are less susceptible to drift. Also, some of these nozzles can be used over a wider pressure range, which produces large droplets at low pressure and small droplets at high pressures. The ability of these nozzles to produce good spray patterns over a wide pressure range makes them an excellent choice to use with rate controllers which control the application rate by pressure changes.

|

| Figure 4. Using a laser to determine spray particle size. |

In a study across the state by weed scientists, five nozzles were compared with various rates of Roundup Weather Max to control several weeds (Figure 5). Since all nozzles performed equally, select the nozzle tip and pressure which have the lowest percent of small droplets. In this situation the Turbo TeeJet, Turbo Flood and Air Induction would all be good choices. The air induction may be the best choice since it is available in ceramic and can be purchased in a combination tip built right into the cap. Several nozzle tip manufacturers have similar nozzle tips. In the United States nozzle tips are classified by droplet spectrum by Standard S-572. This includes using reference nozzle tips at specified operating pressures, water and a laser.

Figure 6 shows how the various nozzle tips are affected by adding Roundup WeatherMax and various additives. With the XR, TT, and TF the Array and Border did increase droplet size and reduced the percent of small droplets. These same additives with the Air Induction nozzle tip did not make for larger droplets and did increase the number of small droplets.

Drift retardants

Drift retardants reduce drift by increasing the viscosity or surface tension of a spray solution. The viscosity of spray mixtures can greatly influence the size of spray droplets produced by atomizers. In the 1970s water thickening additives such as swellable polymers that produce a solution of gelatinous particles were developed and used. Modern drift retardants include polyacrylamides, polyethylene oxides and polysaccharides. It has been demonstrated many times that drift retardants significantly increase the VMD of a sprayed solution when added to the water in a spray tank. After several trips through the sprayer pump some of the drift retardants lose their efficiency and the size of the spray particles is the same as before. Research shows that while some drift retardants may help under some conditions, most drift management should include nozzle selection, boom height, pressure, etc.

Prioritize safety

The environment and human safety are the top priority of any activity. We must handle pesticide safety. With the larger number of people coming into contact with agriculture, we need to be sensitive to their lack of knowledge of agricultural issues. Understanding drift and knowing how to manage it will help most producers avoid problems. Remember, we are responsible for the injury we cause and are accountable for it.

Robert N. Klein

Extension Cropping Systems Specialist

West Central REC, North Platte