Appling nitrogen fertilizer or crop protection products through a center pivot is an efficient and effective method. In fact, it is a well-documented best management practice to apply nitrogen fertilizer as close to the time the corn will use it to get the most efficient use of the fertilizer. Most of the products are injected into the pivot with a fixed rate injection pump. So, how does one figure the pumping rate to set the pump at, and what about the change the end gun causes when it's turned on and off? We will discuss both challenges in this article.

The key to knowing the correct setting for the chemigation pump is to determine how many acres per hour the pivot will cover at the desired irrigation application depth or rate. Chemigation injection pumps are calibrated in gallons per hour (gph). So, if you know how much product you want to apply per acre —e.g., 10 gallons/acre — and how many acres the pivot will irrigate per hour — e.g., five acres/hour — then you will know how many gallons per hour the pump will need to deliver.

For example:

10 gallons/acre x 5 acre/hr = 50 gph

The calculation is just this simple, but it takes some effort to determine the acres per hour the pivot will irrigate.

Different methods can be used to determine how many gallons/hour (gph) the chemigation injection pump should be set to inject. We are going to talk about two of them today.

- The first one is using the “speed chart” (water application depth per pass chart) in the “sprinkler chart” for the pivot or looking up circle time on the computer panel or the pivot app.

- The second one involves calculating the chemical injection rate using a spreadsheet. This method gives you more details about the system and is still easy to figure. You will just need to enter the basic information for the pivot. If you are interested, download the spreadsheet from UNL Water.

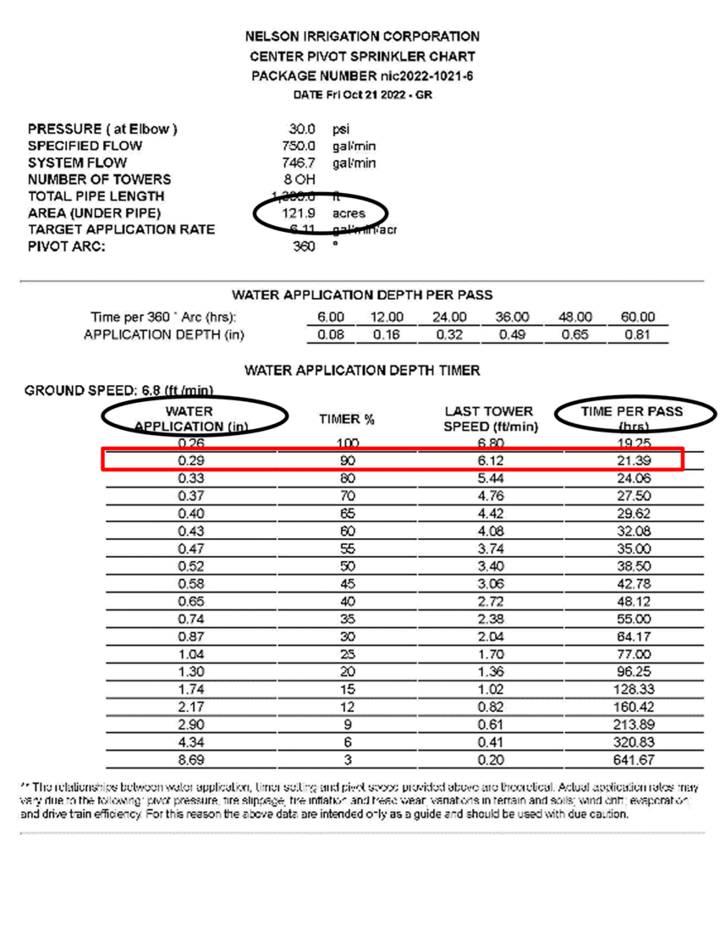

Both methods require the basic information for the pivot. All the needed details can be found on the sprinkler chart for the center pivot. The sprinkler chart is the documentation that came with the sprinkler package for the pivot and describes the basic layout of the pivot, water flow rate, pressure, size of each sprinkler, etc. If the current sprinklers on the pivot came with the machine when it was new, the pivot dealer should be able to provide a copy. Otherwise, ask the company that sold the current sprinkler package for it. If you do not have the sprinkler chart, then you will need to determine the needed data by measuring the pivot.

Determining the Chemigation Pump Setting Using the Sprinkler Chart

The chemigation injection pump setting can be easily determined using the sprinkler chart. The method is very simple to use if one has the chart, or at least the speed chart part of it. The information can also be gained from looking at the readout on a computer-style pivot panel or the pivot control app.

Let’s take a look at an example. We want to apply 0.30 inches of water with the pivot during the chemigation application.

So, by looking on the speed chart, it will take 21.39 hours to complete the circle applying 0.29 inches (which is the closest line on the chart to the desired 0.30 inches).

If we know the acres under the pivot — e.g., 121.9 acres — we can determine the acres per hour.

Example:

121.9 acres / 21.39 hr = 5.7 acre/hr

Note — The acres listed on the sprinkler chart assume the end gun (if equipped) is on the entire field. Thus, use the irrigated acres from another source if the machine is equipped with an end gun.

So, if we want to apply 8.5 gallons/acre of 32% UAN (30 lbs/acre N) with a pivot irrigating 5.7 acres/hour, the pump would need to be set to pump 48.5 gph.

Example:

8.5 g/acre x 5.7 acre/hr = 48.5 gph

The pump would need to be set to deliver 48.5 gph to apply the planned 30 lbs/acre.

OK, That is Great, But I Want to Use My End Gun

The best answer may be to just not use the end gun because of its lower uniformity and the fact that it will lower the nitrogen application rate when it comes on. However, two methods of solving this problem come to mind. The first is to purchase a variable rate injection pump and the second is, if the pivot is equipped with a computer panel, keep using the lower cost fixed rate injection pump and simply slow the pivot down when the end gun turns on.

The two different speeds can be achieved by a simple setup in the computer pivot panel. The degree of rotation at which the end gun turns on, the program simply slows the speed down and then returns it to the faster speed at the time the end gun turns off. The idea is that we want the pivot to cover a constant number of acres per hour. The key is to know how to calculate the slower speed.

The method uses a ratio of the length of the center pivot vs. the throw of the end gun. The designed end gun throw and the length of the pivot can be found on the sprinkler chart.

Let’s look at an example. If we have a pivot that is 1,300 feet long with an end gun having a throw of 100 feet, how much slower should the pivot travel when the end gun is operating to cover the same acres per hour as when the end gun is off?

First, we need to figure the ratio of the end gun throw (Rg) to the pivot length (R).

Ratio of the end gun throw to the center pivot length:

100ft / 1,300ft = 0.0769

Rounded to = 0.08

Table 1 shows how the ratio of Rg/R relates to the pivot speed with the end gun on (Se) compared to the speed with the end gun off (S). Therefore, rounding to 0.08, we can look in Table 1 to find our speed ratio of 0.86.

Using the ratio, multiply the pivot speed by the number in the table to get the speed when the end gun is on. So, for example, if the pivot is set to operate at a 90% timer setting when the end gun is off, it should only operate at 0.86 of that speed when the end gun is on.

Calculate the speed when the end gun is on:

90% x 0.86 = 77.4%

Thus, the pivot should operate at a 90% timer setting when the end gun is off and slow to 77.4% when it is on to apply the 30 lbs/acre nitrogen both when the end gun is off, as well as when it is on. The water application will be different — 0.29 inches when the end gun is off and about 0.33 inches when it is on — but the nitrogen rate will remain the same with the constant injection rate pump. The concept behind this method is that the pivot will irrigate the same number of acres per hour, thus the lower cost fixed-rate injection pump will work correctly.

| Rg/R | Se/S |

|---|---|

| 0.02 | 0.96 |

| 0.03 | 0.94 |

| 0.04 | 0.92 |

| 0.05 | 0.91 |

| 0.06 | 0.89 |

| 0.07 | 0.87 |

| 0.08 | 0.86 |

| 0.09 | 0.84 |

| 0.1 | 0.83 |

| 0.11 | 0.81 |

| 0.12 | 0.8 |

| 0.13 | 0.78 |

| 0.14 | 0.77 |

| 0.15 | 0.76 |

| 0.16 | 0.74 |

| 0.17 | 0.73 |

| 0.18 | 0.72 |

| 0.19 | 0.71 |

| 0.2 | 0.69 |