Spray quality refers to the Internationally Standardized Droplet Size Classification (ASABE S572.1). In this standard, the droplet size spectrum produced by a nozzle is classified as extremely fine, very fine, fine, medium, coarse, very coarse, extremely coarse, and ultra coarse, which describes the spray coverage and spray drift associated with the droplet size. Nozzles with these various spray quality classes are color coded to help with recognition.

The spray quality needed for best efficacy and spray drift management depends on the pesticide, target, carrier rate, application equipment, and environmental conditions.

We always need to manage spray drift so the following discusses this.

Managing Spray Drift

It is estimated that two-thirds of pesticide drift problems involve mistakes that could have been avoided. Drift is of concern because it takes the pesticide from the intended target, making it less effective, and deposits it where it is neither needed nor wanted. The pesticide then becomes an environmental pollutant in the off-target areas where it can injure susceptible vegetation, contaminate water, or harm wildlife. Drift cannot be eliminated but the use of proper equipment and application procedures will maintain the drift deposits within acceptable limits.

There are two kinds of drift:

Particle drift is off-target movement of spray particles.

Vapor drift is the volatilization of the pesticide molecules and their movement off target.

A Mississippi State University study analyzed data from more than 100 studies involving drift from ground sprayers. Of the 16 variables considered, three were most important.

- Wind speed. When wind speed was doubled, drift increased by almost 700% for readings taken 90 feet downwind from the sprayer. Hence the recommendation to spray when wind speeds are 10 mph or less.

- Boom height. When the boom height was increased from 18 to 36 inches, the amount of drift increased 350% at 90 feet downwind.

- Distance downwind. If the distance downwind is doubled, the amount of drift decreases five-fold. Therefore, if the distance downwind goes from 100 to 200 feet, you have only 20% as much drift at 200 feet as at 100 feet. If the distance increases to 400 feet, you only have 4% of the drift you had at 100 feet. Check wind direction and speed when starting to spray a field and continue to monitor while spraying. You may want to start spraying a side of the field where drift could affect nontargets when the wind speed is lower. Also, it may be necessary to only spray part of a field because of wind speed, wind direction, and distance to susceptible vegetation. The rest of the field can be sprayed when conditions become acceptable.

Pesticide drift also can be reduced by using one of the new types of nozzle tips and by adjusting spray pressure. Higher spray pressures produce smaller droplets, which are more susceptible to drift. If using a rate controller, be careful of increased speed, since most rate controllers increase the pressure to maintain the same gpa when the speed increases. Try to maintain the speed within +10%. For example, if you’re applying 20 gpa at 8 mph at 40 psi and you increase the speed to 11 mph, a 37.5% increase, the pressure will now be 75.5 psi. This will produce a lot of small particles prone to drift. Also, be aware that this pressure will be above the operating range of some nozzle tips. Drift reduction agents may be helpful. Slowing down reduces pressure, which increases spray particle size and may reduce efficacy.

Pulse width modulation (PWM) can maintain the desired spray particle size and therefore can be an effective pest management tool. It is not the newest technology; some manufacturers have been offering this for more than a decade.

The original inventor of PWM for spraying, Ken Giles of the University of California at Davis, worked with Capstan Ag Systems to produce the Capstan Synchro, the first PWM system on the market. The Capstan product was later licensed to Case IH sprayers and named AIM Command. It was a factory option on Case sprayers (manufactured by Capstan) from 1998 to 2016. The system featured a separate monitor, permitted PWM to range from 100% down to 15%, and featured an alternating pulse in which every second nozzle pulsed identically, and alternating nozzles worked in a 180-degree offset. In other words, in a system operating at 50% DC, when any given nozzle is on, adjacent nozzles are off. This results in a “blended pulse” that minimizes the likelihood of skips.

Pulse width modulation systems from manufacturers such as Capstan, Raven, and TeeJet operate at a 10 Hz frequency. This means they have 10 cycles per second on a 100-millisecond (ms) cycle to operate solenoids mounted on each nozzle.

For example, a PWM system at a 40% duty cycle means that during each 100 ms cycle, the nozzle solenoid will be in the “On” state for 40 ms and the “Off” state for 60 ms. An 80% duty cycle means the nozzle will be in the “On” state for 80 ms. Therefore, an 80% duty cycle would release twice the amount of product during 100 ms as a 40% duty cycle.

To obtain maximum pesticide efficacy and manage spray drift, an applicator with a conventional sprayer with a rate controller that adjusts pressure to speed is using a carrier rate of 35 gallons per acre when applying paraquat. He is using a large spray particle size to manage spray drift and with the high carrier rate obtains good coverage for good pesticide efficacy. Of course the downside is one cannot spray many acres with each tank and additives that are based on amount of water increase the cost.

The reason many applicators have increased carrier rates is to compensate for uneven speeds because of varying field conditions. These require the product control system to increase and decrease the flow rate in the plumbing system, and thereby the nozzle pressure, to maintain the target product rate. The increase or decrease in pressure changes the droplet size distribution, which affects both pesticide efficacy and spray drift management.

The benefits of a pulse width modulation spray used in spraying pesticides include:

- Uniform spray droplet size distribution

- Compensation for overlaps and turns

- Quick, real-time flow rate changes while minimally impacting droplet size distribution

PWM is not unique to pesticide applications. Some examples of applications of PWM flow control in food processing include:

- Spraying flavors or oils onto bread, pastries, and rice cakes

- Surface coloring with egg coating, milk protein, or caramel

- Moistening dough with water to maintain proper consistency

- Misting bread with water to improve seed adhesion

- Spraying food ingredients onto products or into trays

- Spraying water on hamburger patties, vegetables, and pizza prior to freezing to maintain proper weight

- Spraying antimicrobial agents onto meat and poultry for food safety

- Spraying sunflower oil on peanuts

- Spraying aroma onto coffee and other food products

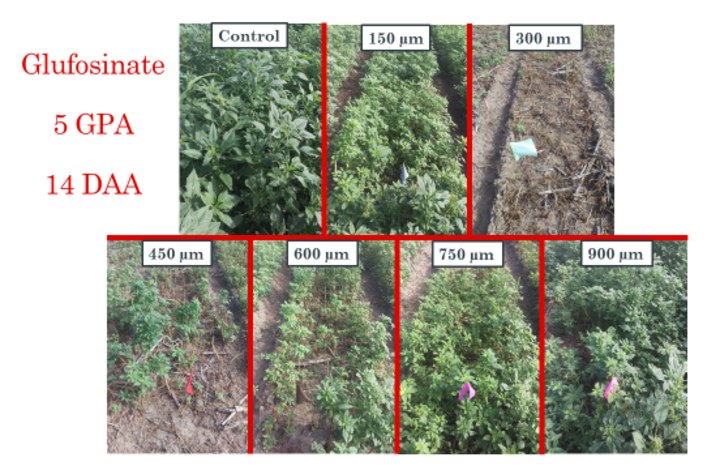

Research by Thomas Butts, graduate research assistant at the University of Nebraska and now the University of Arkansas, showed how spray droplet size and carrier rate affected efficacy.

| Table 1. How spray droplet size and carrier rate can affect efficacy, using glufosinate (Liberty). | ||

| Carrier Volumes | Particle Size | Visual Evaluation Best Spray Quality |

| 5 gpa | Medium | 300 Microns |

| 20 gpa | Medium | 300 Microns |

For both carrier volumes, 750 and 900 microns (ultra coarse), spray droplet sizes were not different from untreated.

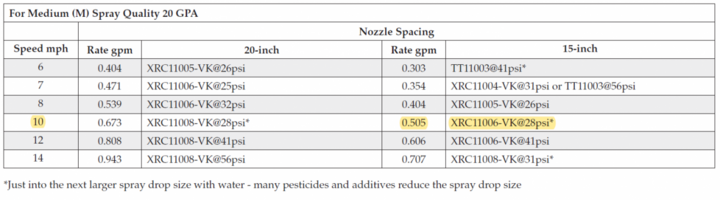

Using a sprayer with a rate control at 10 mph at 20 GPA on a 15-inch nozzle spacing, we use a XRC 11006-VK Nozzle at 28 PSI to obtain the medium droplet size. The slowest we can go with that nozzle is 7.3 mph and maintain 15 psi that results in a coarse droplet size. If we increase the speed to 14 mph, the pressure increases to 55 PSI. This produces a fine-medium droplet size.

**236 – 340 microns

7.3 mph 15.0 PSI Coarse = 341-403 microns

14.0 mph 55.0 PSI Fine-Medium = about 235 microns

With pulse width modulation, we can keep pressure at 40 PSI and maintain the same particle size with speeds from 6.6 to 16.6 mph. We do not recommend speeds over 14 mph.

Summary

By using pulse width modulation, we can increase pesticide efficacy and better manage spray drift and possibly increase efficacy.