With the increased use of dicamba-tolerant (DT) soybeans (Roundup-Ready 2 Xtend), the off-target movement of dicamba to non-DT soybeans and other broadleaf crops is of concern. In 2017 the majority of soybean acreage was planted to non-DT varieties and there were many complaints of dicamba drift, some of which have led to litigation. For example, the Nebraska State Department of Agriculture received over 90 complaints of dicamba drift onto non-DT soybeans with an estimated impact on 60,000 affected acres. Across the Midwest, there were more than 1,000 complaints.

Dicamba spray droplets have a tendency not only to drift with air movement (even very slow wind), but also to move off target when fine aerosol droplets remain suspended during air temperature inversions. These droplets can move from the target site well after the application, even up to 98 hours (four days) after application. This drift can travel long distances (two to three miles, or more) and finally be deposited onto nearby fields with various dicamba-sensitive crops, including non-DT soybeans.

University Research Tests Effects of Micro-Rates of Dicamba Products

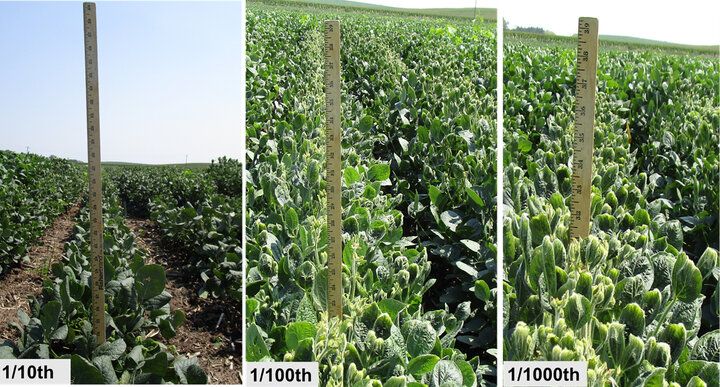

In 2016 and 2017 at the university’s Haskell Ag Lab at Concord we evaluated the influence of micro-rates of dicamba products (Engenia and XtendiMax) to growth, development, and yield of three sensitive soybean types (Round-up Ready, Liberty-Link, and conventional soybeans) at three growth stages of application (second trifoliate, start of flowering, and full flowering). The dicamba rates included: 0, 1/10, 1/50, 1/100, 1/500, and 1/1000 of the product’s labeled rate (12.8 oz of Engenia and 22 oz of XtendiMax). To simplify visuals of the amount of the rates on a per acre basis, one-tenth of the label rate is equivalent to 3 tablespoons and one one-hundredth is equivalent to 1 teaspoon applied over the size of a football field (1 acre).

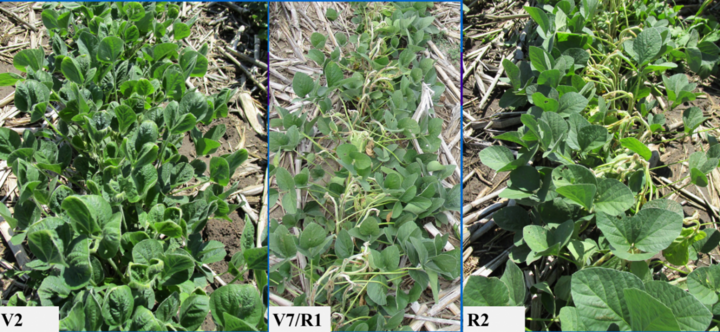

Plots had four rows of each soybean type (Roundup Ready, Liberty-Link, conventional, and dicamba-tolerant as a check). The three application times were second trifoliate (V2), just before flowering (V7/R1), and at full flowering (R2). The V2 timing was chosen to simulate potential drift at an early stage of soybean growth, which would be the earliest expected time for dicamba application. The second and third timings were chosen to simulate potential drift at later soybean growth stages. For example, some fields might be planted earlier, some later, thus these two timings would capture potential drift among neighboring fields around flowering time. Visual evaluation of injuries was conducted at 7, 14, 21, and 28 days after treatment (DAT). Soybean morphological development including plant height, number of branches, days to canopy closure (for V2 and V7/R1 only), days to flowering (for V2 only), number of flowers (V2 and V7/R1), and days to maturity. Yields of all soybean types were harvested.

Roundup Ready, Liberty-Link, and conventional soybeans were equally sensitive to all tested micro-rates of Engenia and XtendiMax. When micro-rates were increased, crop growth parameters were significantly impacted, including: reduction in plant height, alterations in branching pattern, delayed days to canopy closure, and delayed date of flowering, a reduction in flower number, a delayed date of physiological maturity and most importantly, a reduction in soybean yield. The extent of negative impacts depend on correspondence of application date with the soybean growth stage, with V7/R1 stage being the most dicamba sensitive.

Engenia and XtendiMax reduced soybean height by as much as 30 inches, depending on the herbicide rate, which also delayed or completely prevented canopy closure. Almost all rates (1/500 to 1/10) of Engenia and XtendiMax applied during early vegetative stage (V2) delayed soybean flowering by 10 days, across all soybean types. Based on ratings conducted at 65 days after planting, an Engenia rate of 1/10 (1.6 oz/ac) applied at V2 stage led to a 56% reduction in flower numbers and as much as a 92% reduction when applied at V7/R1 stage.

Both dicamba products delayed soybean maturity by 5-25 days, depending on the growth stages of dicamba application and the dicamba rate. Both Engenia and XtendiMax injured non-DT soybean varieties in a similar fashion. The visual injuries ranged from 20%-80%, depending on the growth stage of application and the dicamba rate.

Yields of all non-DT soybeans were significantly reduced by both herbicides irrespective of application time. However, the V7/R1 stage appears to be the most dicamba-sensitive stage, followed by the R2, and then the V2 stages. For example, conventional, Liberty-Link and Roundup-Ready soybeans yielded 58, 60, 60 bu/ac in non-sprayed control plots. However, when the same soybeans were sprayed at V2 stage with 1/10 of the Engenia rate, they yielded considerably less ― 24, 22, and 27 bu/ac, respectively. Yields were further lowered to 18, 15 and 25 bu/ac, respectively, when spraying occurred at R2. However, extremely low yields of only 3, 2 and 4 bu/ac were measured when the spraying occurred at V7/R1 stage. Similar yield responses were measured in plots sprayed with XtendiMax. In most cases, the 1/50 and 1/100 of the labeled rate reduced soybean yields by 13-16 bu/ac when applied at the V2 stage. Yields were also reduced even with “very low” exposures of 1/500 and 1/1000 of the label rate. For example, the 1/1000 of label rate of Engenia applied at V2 stage reduced yields by about 4 bu/ac in conventional, 2 bu/ac in Liberty-Link, and 4 bu/ac in Roundup-Ready soybean. The same rates applied at the V7/R1 stage reduced yields by 11 bu/ac in conventional, 3 bu/ac in Liberty-Link and 8 bu/ac in Roundup-Ready soybean.

Both Engenia and XtendiMax had similar effects on the growth and development of all non-DT soybeans, clearly showing that non-dicamba tolerant soybeans were sensitive to even very low micro-rates of Engenia and XtendiMax, hence, efforts must be made to avoid drift of dicamba onto sensitive soybeans.

For additional information on this research, contact Nebraska Extension Weeds Specialist Stevan Knezevic at sknezevic2@unl.edu.