Nitrogen (N) is essential to plant growth and development. On average, 1.2 lbs of N is needed to produce a bushel of corn, with a 200 bu/ac corn crop needing 240 lbs N/ac. This high demand is partially met through the application of N fertilizer.

Partial factor productivity of N (PFPN), a measure of how many pounds of grain are produced per pound of fertilizer N, can be used to inform N use efficiency (NUE) at the farm level. On average, Nebraska corn farms have a PFPN of 65 lbs grain per pound of N. Assuming a grain N concentration of 1.3%, this means that 0.84 lbs of N is exported in the grain for each pound of N applied as fertilizer. While PFPN does not differentiate N sources (like from fertilizer, soil organic matter, mineralization, residual nitrate, manure and previous crop), it is a starting point for NUE benchmarking. Under high N fertilizer loss scenarios, PFPN will decrease. This means that either 1) less grain was produced due to N stress, or 2) a similar amount of grain was produced at a higher-than-normal N rate to compensate for losses.

Nitrogen Loss Assessment Tool

Producers can use the Nitrogen Loss Assessment Tool (N-LAT, Wortmann et al., 2014) to better understand how their N management practices can be impacted by county-specific soil and weather data. Based on this information, N-LAT calculates long-term average N loss associated with different N management practices for given fields.

For more information about N-LAT, including a link to download the spreadsheet, see the Nebraska Extension publication, Nitrogen Loss Assessment Tool (N-LAT) for Nebraska: Background and Users Guide.

In situations with a high potential for N loss coupled with inappropriate management for loss prevention, low NUE may be due to high N loss because of excessive N supply and asynchrony between N supply and plant N demand. Most agricultural N losses occur due to nitrate leaching, ammonia volatilization, and denitrification.

The degree to which N is lost by different mechanisms depends on

- fertilizer management practices like N application timing, N source, N placement, and N rate, and

- environmental conditions like soil type and weather patterns.

While a nutrient management plan can help decrease the chance for N loss, weather can still play a major role. One way to decrease the impact of unpredictable weather is by using an N fertilizer stabilizer. The decision to use one, however, can be complicated as the decision needs to be made before you know the effect weather will play in a given season. Because of that, it becomes important to understand your management practices, production environment, and how different stabilizers work in order to select the most profitable strategy to reduce N losses, improve NUE, and improve or maintain yields.

Types of Nitrogen Fertilizer Stabilizers

Nitrogen fertilizer stabilizers can be classified into three major types:

- nitrification inhibitors,

- urease inhibitors, and

- slow-release coated fertilizers.

Nitrification inhibitors (NIs) are compounds mixed with ammonium-forming N fertilizers to decrease the rate of transformation of ammonium (NH4+) to nitrate (NO3-). Both N forms are plant-available, but nitrate is prone to leaching and denitrification. Leaching of nitrate-N can cause losses of up to 50% of fertilizer N applied on sandy soils. Denitrification can account for about 15% N losses under low-lying, heavy-texture soils in extreme conditions. Despite this high loss potential with nitrate-N, an NI is only expected to have a positive impact on grain yield when weather patterns favor losses large enough that N becomes insufficient to meet crop needs.

Urease inhibitors (UI) are compounds mixed with urea-based fertilizers to decrease the rate of urea hydrolysis by temporarily blocking the active site of urease enzyme. UIs can be especially important when urea-based fertilizers are surface-applied on high-pH soil and in high-residue conditions like no-till as crop residue contains high concentrations of urease. If unprotected, urea hydrolysis on the soil surface can lead to about 30% fertilizer N lost through ammonia volatilization. UIs protect urea from being quickly hydrolyzed and potentially volatilized before it is incorporated (mechanically or via more than 0.25 inch of rainfall/irrigation) and becomes protected in the soil. Similarly to NI, the UI effect on yield is weather dependent and may only be beneficial if no rainfall/irrigation occurs in the first five days after fertilizer application on drying soil conditions.

Slow-release coated fertilizers are conventional fertilizers such as urea coated with sulfur, polymers, or both. Release of fertilizer through coating is a function of coating characteristics affected by soil water and temperature. Once urea is released through coating, it is exposed to the same transformations in the soil as non-coated fertilizer. The coating technology can provide a gradual supply of N for the developing crop. Soil and climatic conditions can alter the effectiveness of coatings.

Stabilizers, Weather and Yield

In a 28-year study near Clay Center where the NI nitrapyrin was evaluated along with spring-applied anhydrous ammonia on a silt loam soil, a positive yield response was observed 36% of the time. However, a negative yield response from using NI was observed 18% of the time, with the remaining 46% having no effect on yield. NI had a positive impact on yield (from 8 to 13 bu/ac higher than fertilizer alone) when weather during the six weeks after N application included

- moderate-volume, well-distributed rainfall, or

- higher-volume rainfall coupled with higher temperatures.

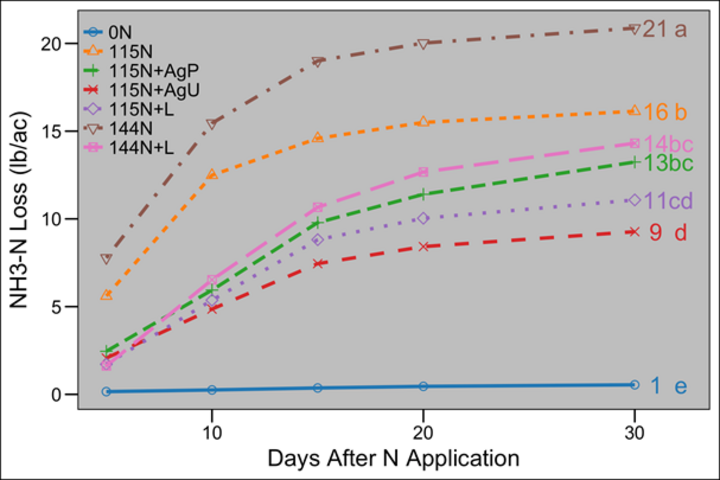

UIs also were tested in central Nebraska the last three years. Nitrogen fertilizer in the form of urea or urea-ammonium nitrate was surface-applied near corn planting time with and without UI. UI only had a positive effect on yield at one site, where UI+urea produced 20 bu/ac more than urea alone. This site received 2.3 inches of rain 5-10 days after fertilizer application. (Also, at four and five days after application, it received rain of 0.03 and 0.09 inches.) Rainfall volumes less than 0.25 are not enough to move fertilizer into the soil yet allow for urea hydrolysis on the surface, increasing volatilization potential. In other years, UI had no effect on yield. In all years, using UI decreased potential ammonia volatilization losses from 3.6 to 13.3 lbs N-NH3/ac less than fertilizer alone, which meant 3%-7% of applied N was not lost (Figure 2).

The three-year study in coarse-textured soil in south-central Nebraska demonstrated the benefit of using polymer-coated urea (ESN®) irrespective of inter-annual climatic variation. ESN consistently improved corn yield compared to UAN at various rates of N application. Averaged across N rates, corn yield with ESN was greater than with UAN by 49%. A laboratory study simulating those field conditions suggested that ESN reduced ammonia loss by 15% in a dry year while in a wet year, it reduced nitrate leaching by 60% compared to UAN.

Recommendations

- N fertilizer stabilizer use will only have a positive impact on yield if weather conditions are conducive to N losses to the point of N becoming limiting in relation to crop demand.

- NI may increase yield with a single application of ammonium-forming fertilizer on irrigated fields. Timing of NI use should allow for high effectiveness in May and June when greatest nitrate-N leaching commonly occurs.

- UI is more likely to have a positive impact on yield when urea-based fertilizer is surface-applied on high-pH (more than 7) and low cation exchange capacity soil with high residue cover, where no incorporation (mechanical or rainfall) occurs in the first five days after application on a drying soil.

- ESN is more likely to have a positive impact on yield when field conditions represent extremes for weather risk of N loss to leaching, volatilization, or denitrification.