This the first of a three-part series on how to decide whether you want to use in-canopy sprinklers or sprinklers at truss rod height or above on a center pivot. The paper was originally published in the proceedings of the 2018 Central Plains Irrigation Conference and has been adapted for CropWatch. Featured here, part 1 of the series addresses water losses from a center pivot and when to replace an existing sprinkler package. Part II will focus on basic sprinkler package design. Part 3 will review differences between in-canopy and above-canopy sprinklers and discuss design considerations for in-canopy sprinklers.

Selecting the proper sprinkler package for a center-pivot or lateral-move irrigation system is essential to efficient operation. New pivots that have the latest control options but a poorly designed sprinkler package will not perform adequately. Frequently, insufficient consideration is given to selection of the best type of sprinkler device for a new pivot or an existing system that’s being updated. Sprinkler devices and their associated operating pressure are often selected based on traditional choices, new promotions, or the lowest capital cost without adequate consideration of local conditions. Characteristics specific to the field, supply pump, and sprinkler package should all be considered.

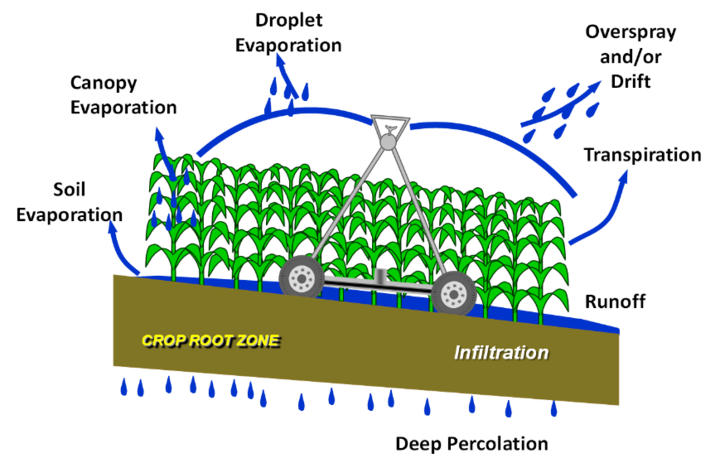

Our objective is to highlight consequences of design choices and explain how decisions affect the uniformity, application efficiency, and quantity of water lost from a center pivot. An important consideration is the placement of sprinklers in or above the crop canopy. The definition of above canopy sprinklers for the purpose of this article is any device operating above the crop, including truss rod height even when corn tassels are up around them. The top of the corn canopy is fairly open and has minimal effect on the pattern.

We explain the selection of sprinkler devices and considerations for the mounting height, the flow rate in gallons per minute for the pivot, and the sprinkler operating pressure. After determining these factors, the details of the design can be developed in consultation with sprinkler or pivot distributors or manufacturers.

Determining When to Replace an Existing Sprinkler Package

Planning for a new pivot or renovation of an existing pivot requires a decision on what sprinkler package to purchase. Sprinkler devices generally do not last as long as the pivot itself and should be replaced as needed. The industry recommends replacement after 10 years or 10,000 hours of operation, whichever comes first, and is extremely dependent on water quality. Additionally, newer sprinkler designs offer more options and can be designed to better suit field conditions than older packages could be. In many situations, updating to a newer design is worth consideration.

When updating your sprinkler package, also replace pressure regulators. They may wear out or break before sprinkler devices and/or new sprinkler packages may require a different pressure than the original design.

Water Losses from Center Pivots

Improving the application efficiency of the center pivot is often the goal of lowering sprinkler devices into the canopy. Operators should understand what factors affect water losses and the magnitude of the losses.

Water “losses” from a pivot are caused by several factors:

- Droplet evaporation while water travels through the air

- Drift of droplets from the field or to a location with a dry canopy

- Canopy evaporation after wetting crop leaves

- Evaporation directly from the soil

- Runoff from the field or to low areas within the field causing deep percolation losses

- Deep percolation from the crop root zone due to excess application or poor uniformity

- Transpiration through plant leaves

Research Documents How Water Loss Occurs

Research at Bushland, Texas showed that impact sprinklers placed on top of the center-pivot pipeline were about 85% efficient in applying water to the soil, while spray heads on drops at truss-rod height were about 92% efficient. Low energy precise application (LEPA) irrigation systems could be up to 98% efficient if operated perfectly. This experiment was conducted mid-day with temperatures of 88°F, wind speeds above 15 mph, and a relative humidity of about 36%. The water supply rate was about six gallons per minute per acre with an application of one inch of water after the corn canopy had reached its full height.

- The 2% loss from the LEPA system was from soil evaporation during the day of application.

- The 8% loss from the spray devices was determined to be 1% from droplet evaporation and drift, 3% from canopy evaporation during the application, and 4% after the water was applied as the canopy dried.

- The 15% loss from the impact sprinklers on top of the lateral was determined to be 3% from droplet evaporation and drift, 8% evaporation from the canopy during the application, and 4% from canopy evaporation as the crop dried.

The field was quite flat and consisted of a Pullman clay loam soil. The LEPA portion included basins to store water applied at rates that exceeded the infiltration rate of the soil. Thus, the soil/plant conditions and field slope were well matched to optimal performance for LEPA systems. Runoff and/or redistribution due to reduced uniformity from local runoff were minimal. Thus, the losses for the experiment reflect losses due to evaporative effects and not runoff or nonuniformity.

In-Canopy Water Loss

Water loss as the canopy dries after an irrigation is the same regardless of the amount of water applied. In the study described here, loss was 0.04 inches. When 0.5 inch was applied, the loss was 8%, but when 2 inches was applied, the loss per application dropped to 2%.

The evaporative losses must be considered relative to the depth of water applied. The study used an application depth of one inch, resulting in a 4% or 0.04-inch loss after the sprinkler had passed—i.e., while the canopy dried. The water loss after irrigation as the canopy dries is unrelated to the depth of water applied as long as the canopy is thoroughly wetted. Thus, when only 0.5 inches is applied, the loss would still be 0.04 inches, resulting in an 8% loss. Conversely, if 2 inches were applied, the loss would only be 2%. Evaporation from the canopy while water is applied depends on the duration of the application and the depth of water applied. If the amount of water applied for the year is the same for different application depths, then cumulative losses that depend on the depth of water applied per irrigation will be the same for the year because the canopy will be wetted the same amount of time.

Evaporation and transpiration depend on the amount of energy available to evaporate water. The energy comes from solar radiation and hot dry winds, which are the same for all areas of the field. Research has shown that transpiration is suppressed while the crop is wetted; thus, energy is available to increase evaporation rates when transpiration decreases. There is more resistance to vapor flow for transpiration than evaporation from the canopy; thus, the reduction in transpiration may be less than the amount of evaporation from the canopy while irrigating and/or drying.

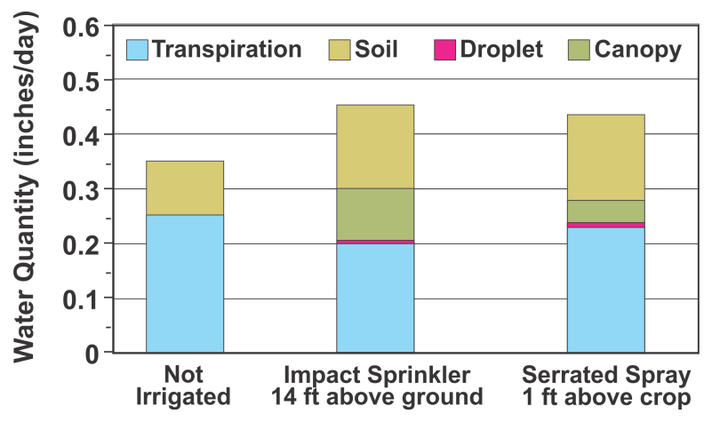

An experiment was conducted where a portion of the field was irrigated with spray devices at the truss rod height and impact sprinklers atop a lateral-move system. The experiment included a portion of the field that was previously irrigated so soil water was adequate to avoid crop water stress; that portion of the field was not irrigated.

Distinguishing Losses from Transpiration and Evaporation

The partitioning of the transpiration and evaporation fluxes is shown in Figure 2. The transpiration for a dry canopy was about 0.26 inches/day, while transpiration for spray devices was about 0.22 inches/day and 0.20 inches/day for the impact sprinklers. The reduction of transpiration was about 0.06 inches/day for impact sprinklers and 0.02 inches/day for spray devices. The transpiration rate for the irrigated areas returned to about the same rate as the non-irrigated area once the canopy dried. Evaporation from the canopy was approximately 0.1 inches/day for impact sprinklers with a larger diameter of throw than spray devices where the canopy evaporation is about 0.04 inches/day. Therefore, the net canopy evaporation for impact sprinklers is about 0.04 inches/day and for spray devices, about 0.02 inches/day.

Irrigation also increased soil evaporation for the day of irrigation. The increase in soil evaporation above that for the nonirrigated area was about 0.05 inches/day for either sprinkler device—note that evaporation from wetted soil may extend beyond one day. These results are representative of a typical system during a near normal day in the Southern High Plains; however, different systems and days would produce different results.

Designing Sprinkler Packages to Minimize Losses

Sprinkler package design can affect many of the water pathways shown in Figure 1. Designs should consider how to minimize losses while considering effects on the overall function and economics of the system. For example, evaporation of water while drops travel through the air is strongly affected by the size of the droplet. Large drops are less affected by wind and evaporate at a much smaller rate than drops smaller than 0.04 inches in diameter. The newer sprinklers are much better at controlling the size of drops, allowing for minimization of droplet evaporation while avoiding damage to unprotected soils.

Research shows that even in a hot dry windy climate like the Southern High Plains, the water loss from the sprinkler to the soil is small and a small amount of runoff that causes water to move within the field will more than offset gains from locating sprinklers in the canopy. The primary objective for the sprinkler package must be to have the water infiltrate into the soil at a high enough uniformity so each plant has an equal chance to access water.

Next Week

Please watch for the next issue of CropWatch when we will talk about basic sprinkler package design.

Resources

For more information on irrigation and water management, see related CropWatch stories at cropwatch.unl.edu/tags/irrigation and the Agricultural Production section of Nebraska Extension's Water.unl.edu.